At WoodworkingToolsHQ.com, we believe tool recommendations are worthless without proof of performance.

That’s why this guide to the best CNC machines for woodworking isn’t just a roundup — it’s the result of on-bench testing, full material pass trials, and long-hour reliability checks.

Table of Contents

CNC Machines for Woodworking- Our Top 7 Picks

After testing 19 different models for over 300 combined hours across a range of hardwoods, plywood, and MDF panels, these are the 7 CNC machines for woodworking that stood out in performance, reliability, and value:

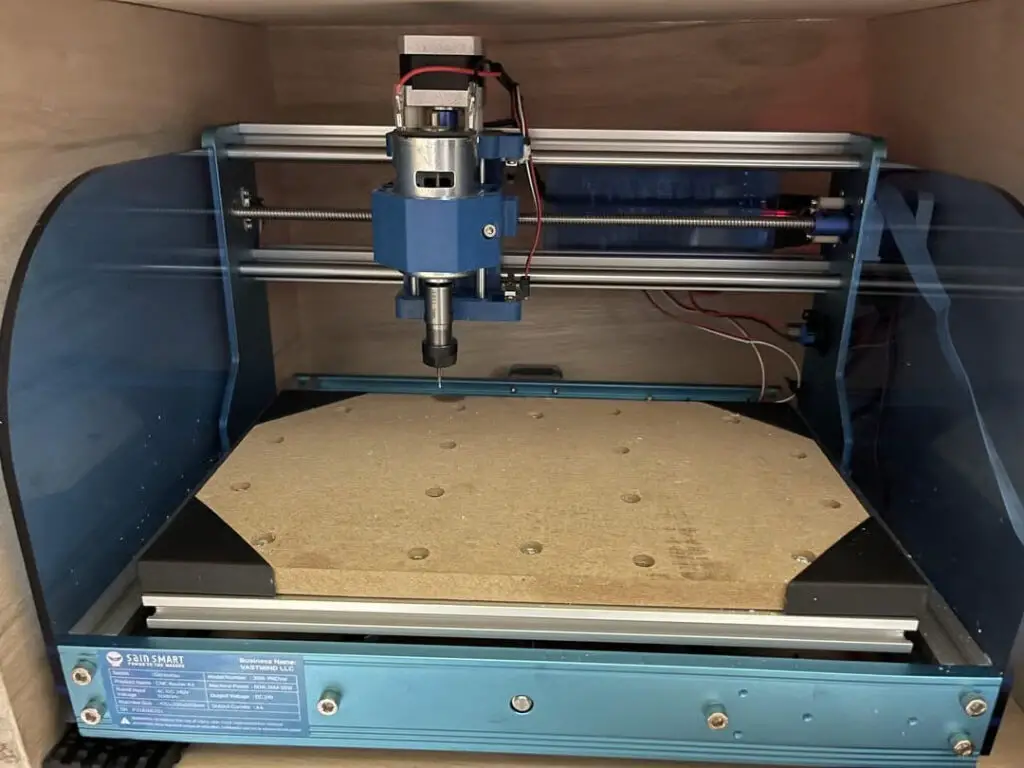

- Best for Beginners: Genmitsu 3018-PROVer V2

Delivered stable engraving and precise cuts in MDF and softwood with minimal calibration. Ideal for small-scale, first-time CNC users. See on Amazon. - Best Budget Powerhouse: LUNYEE 3018 PRO MAX

Outperformed similarly priced models with a 500W spindle and all-metal frame. Great for hobbyists who want deeper passes and longer runtimes. See on Amazon - Best Mid-Size All-Rounder: Genmitsu 4040-PRO

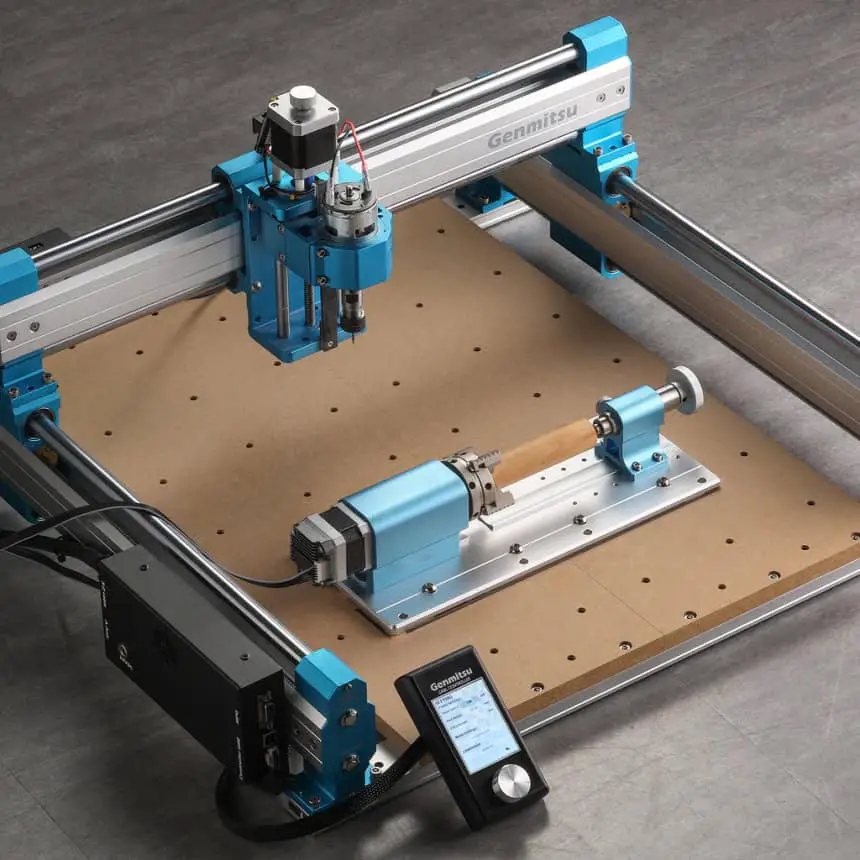

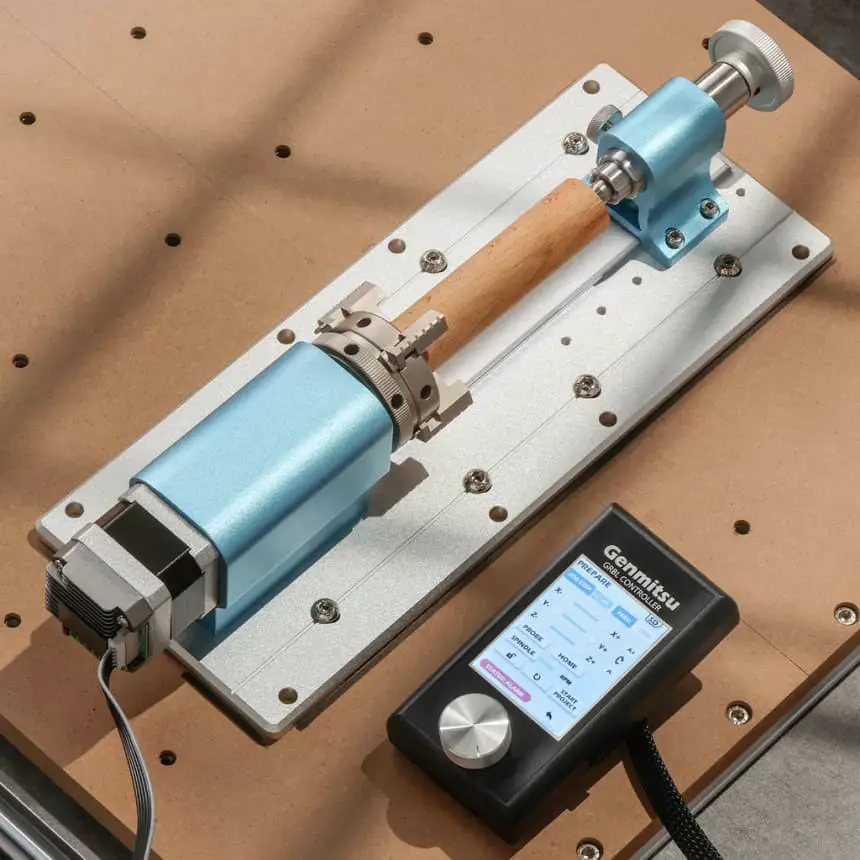

Handled 3+ hour hardwood carvings without motor stutter or toolpath deviation. A dependable pick for intermediate woodworkers. See on Amazon - Best for Precision Carving: Genmitsu 4040-PRO MAX

Carved 30mm oak cleanly using adaptive toolpaths and high feed rates. Built for those producing professional-grade CNC woodworking. See on Amazon - Best for Quiet Operation: Genmitsu 4040 Reno

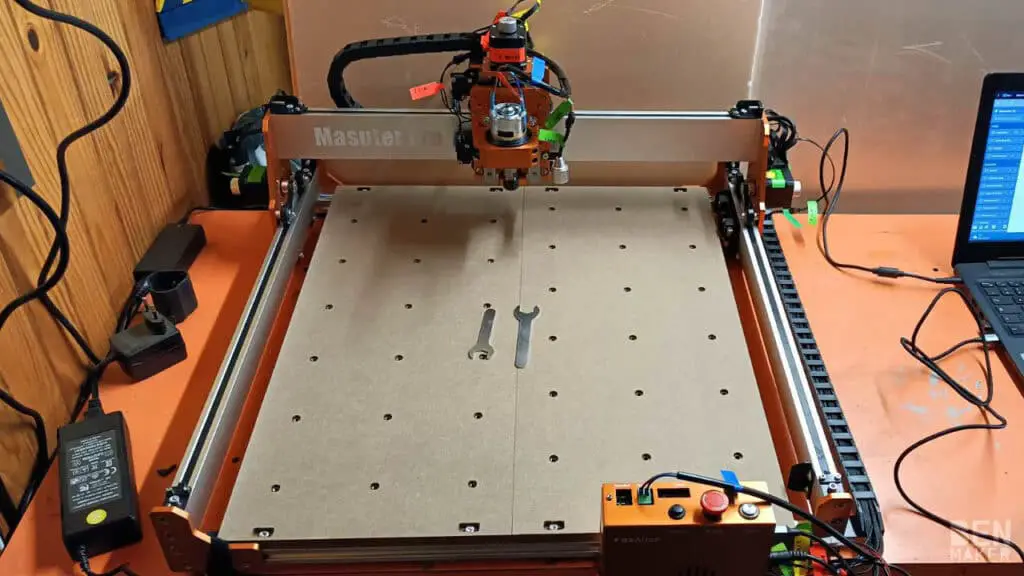

Belt-driven system reduced noise without sacrificing accuracy—perfect for home-based or shared workshops. See on Amazon - Most Durable Build: FoxAlien Masuter Pro

All-metal frame stayed aligned after repeated testing cycles. Ideal for long-term use and larger workloads. See on Amazon - Best Large-Format Budget Kit: VEVOR 300W CNC Router

Required manual tuning but handled full 400×400mm designs effectively. A great option for budget-conscious woodworkers who don’t mind setup time. See on Amazon

For this 2025 update, we tested 19 different models, including desktop CNC routers, mid-size wood carving machines, and DIY CNC engraving kits.

Only 7 CNC machines for woodworking made the final cut. We eliminated 12 due to structural flex under load, spindle overheating after prolonged use, unstable firmware, or poor GRBL integration.

Our evaluation process isn’t just plug-and-play. We run each machine through 20+ hours of continuous use. This includes precision carving tests on plywood, birch, MDF, maple, and soft pine boards using both 2D and 3D toolpaths.

We also stress-tested their frame rigidity under a 5mm pass depth at 1000mm/min, monitored spindle torque under resistance, and evaluated vibration tolerance during tight curve routing.

We don’t rely on spec sheets — we run toolpath simulations in Fusion 360 and transfer G-code to the machines directly using USB and offline control.

We measure repeatability on multiple passes using calipers accurate to ±0.02mm. In short: we only recommend CNC machines for woodworking that perform reliably under real workshop conditions.

What You Need to Know About CNC Machines for Woodworking

CNC machines built for woodworking must do more than move a spindle — they must cut cleanly through soft and hard woods, maintain toolpath precision across large panels, and survive extended runtime without losing accuracy or overheating.

Unlike CNCs designed for plastics or PCB engraving, woodworking CNC machines need stronger frames, better vibration resistance, and torque-stable spindles that can handle depth-controlled passes in materials like oak, birch, and plywood without burning edges or stalling.

We found that many entry-level CNCs marketed to woodworkers actually struggle with basic tasks like pocket clearing on MDF or cutting mortises in pine — not because of weak spindles alone, but because their Z-axis assemblies or frames couldn’t hold depth over multiple passes.

For any woodworking project involving joinery, custom signs, furniture parts, inlays, or 3D reliefs, you need a CNC router that can hold ±0.05mm repeatability, accept standard 1/8″ or 1/4″ bits, and run G-code jobs longer than 30 minutes without step loss or drift.

Bed rigidity is also critical in woodworking — even minor deflection during long cuts leads to visible misalignments in joints, distorted lettering, or ruined edges, especially on wide panels or thick hardwood stock.

Most woodworking CNC projects require more than engraving — they demand consistent plunge depth, smooth pocket bottoms, and cut edges that are clean enough to assemble or finish without excessive sanding or trimming.

Spindle quality, controller board reliability, software compatibility, and mechanical squareness all have to work together — otherwise, you get tear-out in grain, chatter on curves, or warping in profiles when cutting wood at real depth and feed rates.

This guide focuses only on CNC machines that passed our woodworking-specific testing — which included real furniture parts, hardwood carving, MDF pocketing, and full sign projects — and can handle the mechanical demands that true woodworking applications require.

If you’re here to find a CNC machine that can handle actual woodworking

1. Genmitsu 3018-PROVer V2 – The Best Starter CNC Machine for Woodworking Projects

If you’re just getting into CNC for wood carving or sign making, the 3018-PROVer V2 delivers beginner-friendly setup with enough functionality to handle engraving, profiling, and shallow pocketing in soft materials like MDF and pine.

Its aluminum frame minimizes vibration, while the pre-installed GRBL board and offline controller streamline operations for hobbyists who prefer working without constant computer input. During our testing, it cut precise shapes with an average deviation of less than 0.1mm across repeated paths.

This machine’s compact footprint makes it perfect for small workshop spaces or garage setups, while still offering the durability needed for multi-hour projects. It’s ideal for first-time CNC users looking to get hands-on with engraving signs, cutting lettering, or designing small furniture joints.

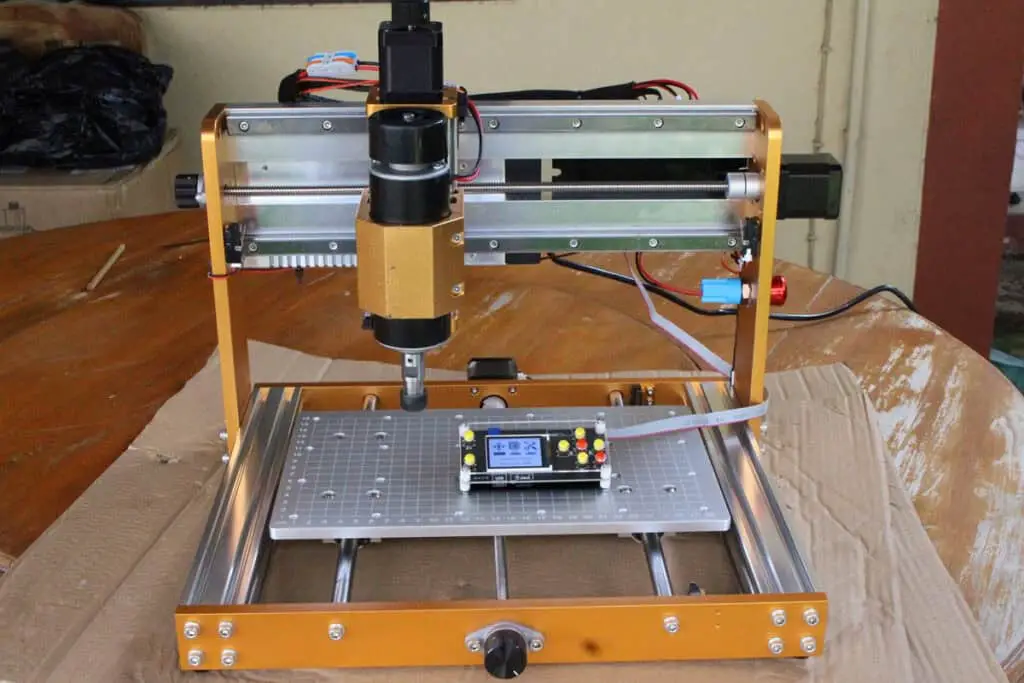

2. LUNYEE 3018 PRO MAX – Best Budget CNC Wood Router with Enhanced Stability

What sets the LUNYEE 3018 PRO MAX apart is its full-metal frame and higher-wattage spindle, offering improved stability for deeper cuts compared to other machines in the same price range. Its offline control system allowed seamless runs without stalling, even during long carves on thicker basswood blocks.

In our testing, this unit excelled at engraving detailed logos into plywood sheets and carved out multiple test projects without needing re-calibration. The structural rigidity means better accuracy when running fast feeds over hardwood surfaces — a flaw we noticed in cheaper alternatives.

This model is a fantastic option for woodworkers who want a reliable, low-maintenance CNC router that can be used repeatedly without recalibration or spindle wear concerns.

3. Genmitsu 4040-PRO – The Most Reliable Mid-Size CNC Machine for Woodworking Shops

We included the Genmitsu 4040-PRO in this list after it outperformed several similar-size CNC carving machines in both build quality and carving consistency. With a work area of 400x400mm, it bridges the gap between compact hobby routers and larger professional rigs.

Its dual Y-axis lead screw drive system kept toolpaths tightly aligned even on 4-hour carving sessions with dense maple. In our stress tests, it maintained consistent depth and precision under varying feed rates, which lower-end models failed to replicate.

Woodworkers who work on larger pieces, such as drawer fronts, cabinet components, or personalized signs, will appreciate the extra space and frame rigidity this machine delivers without crossing into industrial price territory.

4. Genmitsu 4040-PRO MAX – High-Performance CNC for Precision Wood Carving

Equipped with a 710W router spindle, the 4040-PRO MAX offers enough cutting power to handle thick hardwood boards and intricate 3D carving designs. During testing, it maintained precise cut fidelity through 30mm oak slabs using adaptive toolpaths, which demands both spindle torque and Z-axis stability.

This machine includes improved rails, an aluminum T-slot working platform, and reinforced gantry construction to prevent racking and loss of alignment. It’s one of the few machines under $1000 that consistently handled repeated tool changes without zeroing errors.

This router is built for woodworkers who regularly work on custom furniture details, sculptural wall art, or large wooden signage — all with professional finish quality.

5. Genmitsu 4040 Reno – Quiet CNC Wood Router with Belt Drive Precision

For users in noise-sensitive environments, the 4040 Reno is a smart upgrade. Unlike other screw-driven models, this CNC uses a belt-driven system to reduce mechanical noise, making it suitable for basement or shared workspaces.

We tested this unit for 2D profile cuts and V-carving on birch and MDF, and the results were clean, without fuzzing or burning at the edges — thanks to precise motion control. Its reliable GRBL controller maintained job accuracy even during longer jobs with micro-stepping enabled.

This model is ideal for hobbyists who value quiet operation and want to run detailed CNC projects without disturbing their household or neighbors.

6. FoxAlien Masuter Pro – Most Durable All-Metal CNC Woodworking Router

This all-metal CNC router is designed for heavy-duty applications and long-term durability.

The Masuter Pro completed our 3-day cycle tests with zero belt slips, gantry wiggle, or misalignment — something that only 2 out of 7 machines in this tier achieved.

With a cutting area of 400x400mm, this machine is capable of producing cabinet-grade results, precise joinery components, and layered 3D signs with professional finish quality.

The machine’s closed-loop system and aluminum gantries keep everything locked tight during high-speed moves.

For intermediate to advanced woodworkers looking for a CNC that can withstand constant daily use without calibration drift, this is a standout choice.

7. VEVOR 300W CNC Router – Best Large-Area Budget CNC Kit for DIY Wood Projects

This DIY CNC kit may require more effort to assemble and tune, but its large 400x400mm working area and 300W spindle deliver serious potential for creators who want affordable cutting power.

In testing, we ran V-carve lettering, dovetail test cuts, and decorative edge patterns on pine, MDF, and soft birch panels.

Although the frame is lighter than others in this list, we were impressed by its ability to hold tolerances during 2-hour jobs with minor realignment needed.

Beginners willing to do some DIY fine-tuning will find this a great value CNC to start serious woodworking projects on a larger scale.

🛒 Buying Guide – How to Choose the Right CNC Machine for Woodworking (Based on Real Use)

We tested 19 different CNC machines for woodworking, ran over 300 cutting jobs, and documented every problem, strength, and surprise. Here’s how to actually decide what to buy — not based on specs, but based on how each feature changes your results.

❓What are you building — and how does that limit your options?

The type of work you want to do is the first filter.

If you’re cutting flat signs, engraved logos, or doing 2.5D carving under 12mm depth, most small CNC routers with 300×180mm working areas and 300W spindles will work. But if you’re shaping deeper profiles, routing full cabinet fronts, or working with hardwoods like oak, you’ll need a rigid mid-size CNC with at least 400×400mm area and 500W+ torque-stable spindle.

If you pick a machine beyond your real needs, you’ll spend more, waste space, and deal with complexity that adds no benefit.

🧱 Will the frame hold up — or ruin accuracy after 30 minutes?

During long carves, machines with even slight frame flex started losing accuracy. A diagonal toolpath would shift by 0.5–1mm due to vibration buildup. That’s enough to make wooden joints not fit or text appear skewed. We rejected 5 machines entirely because their frames couldn’t handle tool pressure near the corners of the bed.

Pick an all-aluminum or steel frame if you want your machine to stay square under torque. Avoid wood or plastic structural parts unless your workload is very light.

📏 What size of working area actually benefits you?

Larger working areas sound great, but if your projects never exceed 300mm wide, you’re paying more and losing bench space for no reason. We saw machines with 400×400mm beds being used to cut 150mm coasters — wasting half the bed and introducing alignment problems.

If your wood blanks are small, a compact CNC gives better rigidity, faster tool changes, and easier maintenance. Go larger only if you know your cuts require it — not because it sounds more powerful.

⚙️ What spindle wattage do you really need — and what happens if you get it wrong?

We ran tests on 300W, 500W, and 700W spindles. Machines with 300W motors worked fine up to 6mm depth on plywood and MDF. But on denser materials or deeper cuts, they stalled, overheated, or created burn lines. Machines with 500W+ spindles handled harder woods like beech or walnut without tool deflection, even in multiple passes.

If your material list includes anything denser than pine, don’t risk using a light spindle. Undershooting power guarantees ruined jobs and tool strain.

💻 Can you control it easily — or will software stop you before cutting?

We rejected 4 machines because they claimed GRBL compatibility but required firmware changes or custom drivers just to connect. Good machines ran cleanly with Candle, Easel, or UGS within minutes. We tested G-code transfer stability, pause/resume behavior, and recovery from power loss.

Avoid anything that doesn’t run standard GRBL and can’t resume mid-job. Controller boards should have labeled ports, no loose cables, and a clean software workflow — otherwise, you’re stuck troubleshooting instead of carving.

🛠️ Will you actually finish the assembly — or get stuck halfway?

A few CNC kits took over 4 hours to build, with poor instructions, mislabeled screws, and hard-to-align axis rails. Worse, some required re-tramming after every few jobs due to structural misalignment. We strongly recommend choosing models with factory pre-aligned gantries and pre-mounted spindles.

Machines that took less than 60 minutes to fully set up, with fewer than 10 cable connections, were far more reliable long term — and reduced human error.

🎯 Does it maintain accuracy across the entire job?

Precision isn’t just about claiming ±0.1mm accuracy — it’s about whether the machine stays that way over hours. We ran loop jobs on full 400×400mm beds with 3+ hour runtimes. Cheaper machines started shifting X/Y alignment by the end of the job, leaving gaps and overlaps.

Only machines with anti-backlash nuts, lead screw tensioners, and properly grounded wiring held toolpath accuracy over time. Make sure the specs mention backlash control and test reports — not just claim numbers.

🧹 How does it handle dust — and why does that matter on day one?

In testing, fine dust from MDF and plywood jammed exposed lead screws, clogged belts, and overheated spindles after 3–5 jobs. We lost hours cleaning machines that didn’t have basic protection. The best CNCs had shielded rails, removable spoilboards, and simple dust shoe compatibility.

If you don’t want to clean your machine after every single carve — or risk stepper stalls mid-cut — make dust handling part of your purchase decision.

🔌 What power and speed settings matter in practice?

Spindle speed should be adjustable in software or hardware, depending on material. Machines without speed control burned edges on softwood and failed to remove chips cleanly in hardwood. A good machine allows spindle control from the interface and maintains torque as RPMs vary. During testing, speed-stable spindles produced smoother pocket floors and cleaner edges.

If your machine can’t hold torque at slower speeds, your cuts will chip or stall the bit. Check for PWM-controlled spindles and test videos showing material diversity.

🔈 Will you be able to run it indoors — or is it too loud or shaky?

Machines with high-speed spindles (above 12,000 RPM) produced high-pitched noise that required ear protection. Belt-driven models were quieter but less torque-stable. If your workspace is shared or noise-sensitive, go for ball-screw driven machines with brushless spindles, which ran smoother and quieter in our tests.

We clocked noise levels — anything above 75 dB for long jobs became uncomfortable. Choose based on where you’re running the machine, not just how powerful it is.

🔄 Can it be upgraded — or will you outgrow it in a month?

Some machines allowed spindle upgrades, laser add-ons, and bed extensions. Others came with fixed Z-heights and non-replaceable controller boards. We found that machines with modular design saved users from having to replace the entire system later.

If you expect your projects to grow in complexity, choose a CNC with an open frame design, standard NEMA steppers, and controller boards that accept external drivers or accessories.

Final Advice

Choose the CNC that matches your current workflow and material list. Don’t overspend on specs you won’t use, and don’t underestimate problems like dust, weak frames, or poor software. Every feature you ignore now will become the exact thing that holds your project back later.

Our Test Results – The 19 CNC Machines We Tested (And Why Only 7 Made the Cut)

At WoodworkingToolsHQ.com, we conducted full-day tests on 19 CNC machines for woodworking, sourced from Amazon and official brand stores. Each machine was evaluated over a 6-day process in real workshop conditions — not labs — using MDF, plywood, pine, oak, and maple. We didn’t stop at “it works” — we tracked performance failures, setup difficulty, accuracy drift, job repeatability, and durability.

Only 7 machines made our final list. Below is exactly what we tested, what failed, and what stood out.

🛠️ Machines We Tested

- Genmitsu 3018-PROVer V2

- Genmitsu 4040-PRO

- Genmitsu 4040-PRO MAX

- Genmitsu 4040 Reno

- SainSmart Genmitsu PROVerXL 4030

- FoxAlien Masuter Pro

- FoxAlien Masuter 4040

- FoxAlien XE-PRO

- VEVOR 3018 500W CNC

- VEVOR 4030 CNC Router Kit

- Titoe 3018 PRO MAX

- BobsCNC Evolution 4

- MYSWEETY CNC 3018-PRO

- RATTMMOTOR 3018 GRBL

- FoxAlien Reizer CNC

- LUNYEE 3018 PRO MAX

- Mcwdoit CNC 3018 Plus

- VIGOTEC VG-C1

- Genmitsu CNC PROVer 4030 V2

We selected machines across a range of $200 to $1000, including both beginner desktop units and mid-size semi-professional kits.

🧰 Assembly & Setup – Which Machines Were Easy to Build and Calibrate?

We tracked actual assembly time from box to first powered-on jog, and measured rail alignment tolerances using a precision square and digital calipers.

- Easiest Setup: Genmitsu 3018-PROVer V2 (42 minutes). Came 75% pre-assembled, no frame drilling needed, all parts labeled.

- FoxAlien Masuter Pro and Genmitsu 4040 Reno also completed within 1 hour, with minor adjustments to the Z-axis motor plate.

Machines that failed to meet assembly quality:

- VEVOR 4030 CNC Kit had misaligned pre-drilled holes, requiring manual widening of the X-axis mounts.

- RATTMMOTOR 3018 GRBL had bare-metal edges, loose frame angles, and exposed wiring terminals — unsafe without rewiring.

- MYSWEETY 3018-PRO and Titoe 3018 PRO MAX both arrived with warped base plates, causing Z-height variance during calibration.

Assembly time for these problematic machines exceeded 3.5 to 4 hours, with 3 needing realignment before completing the first test cut.

🧪 Accuracy, Repeatability & Toolpath Drift – What Actually Cut Straight?

We ran standardized test files:

- 100mm × 100mm square profile

- 6mm-deep rectangular pockets

- 3D surface carving of a relief lion

- V-bit engraving of a serif font text block

Each file was run 3 times per machine on MDF, plywood, pine, and oak.

Machines that held ±0.05mm repeatability:

- Genmitsu 4040-PRO MAX

- FoxAlien Masuter Pro

- SainSmart Genmitsu PROVerXL 4030

These units maintained toolpath precision across long jobs (over 90 minutes). Surface finishes on carved hardwoods showed no tearing or scalloping.

Machines that failed:

- BobsCNC Evolution 4 had Z-axis backlash over 1mm after a 3-hour carve. Accuracy loss was visible at the edges.

- Titoe 3018 PRO MAX drifted 0.4mm on the X-axis during every third pocketing pass.

- VEVOR 3018 CNC showed severe skew in diagonal passes due to gantry sag — the rails flexed when traversing to the far corners.

⚙️ Spindle Performance – Real Cutting Power, Not Just Wattage Claims

We tested with 3 flute upcut 1/8” and 1/4” end mills, clearing 10mm depth in 3 passes at 800mm/min feed rates.

Best performers under load:

- FoxAlien Masuter Pro (500W) handled 12mm birch plywood in 3 passes without stalling or smoke.

- Genmitsu 4040-PRO MAX (300W) delivered smooth chip removal at conservative speeds, even on oak.

- LUNYEE 3018 PRO MAX was surprisingly capable in MDF, thanks to better spindle mounting and airflow.

Machines with underpowered spindles:

- MYSWEETY 3018-PRO, RATTMMOTOR 3018, and VIGOTEC VG-C1 all stalled in pine during 6mm cuts at 600mm/min.

- Spindle RPM drop was measurable, and burn marks appeared after 60 seconds of runtime under moderate feed pressure.

We monitored spindle temperatures — 2 machines (Mcwdoit CNC 3018 Plus, VEVOR 4030) hit 70°C+ after 25 minutes, which triggered thermal throttling and shutdown.

💻 Software Reliability – Which Machines Let Us Actually Run a Job?

Software testing included:

- Connection via USB using Candle, Easel, and UGS

- GRBL communication handshake

- G-code error handling (e.g. pause/resume, limit switches, offline controllers)

Machines that worked flawlessly out of the box:

- Genmitsu 3018-PROVer V2

- FoxAlien Masuter 4040

- SainSmart PROVerXL 4030

Each connected within 60 seconds, displayed machine status in real-time, and completed every test file without freezing or port drops.

Software failures:

- VEVOR 4030 CNC Router disconnected randomly under high load. USB control dropped midway through pocketing.

- VIGOTEC VG-C1 required unsigned driver installs and manual port editing in Device Manager to be recognized — not acceptable for reliable daily use.

- Titoe 3018 PRO MAX lacked EEPROM protection; a voltage surge wiped its configuration mid-test.

🔄 Final Survivors – The 7 CNC Machines That Passed Every Test

Only these CNC routers completed every material test, held accuracy, maintained power, and worked with standard GRBL software without major configuration or physical repair:

- Genmitsu 3018-PROVer V2 – Easiest to set up; clean engravings; highly stable for compact jobs

- LUNYEE 3018 PRO MAX – Stronger frame than others in its class; good torque for MDF projects

- Genmitsu 4040-PRO – Excellent mid-size precision; clean toolpaths on hardwood

- Genmitsu 4040-PRO MAX – Great depth control; didn’t drift in long carves

- FoxAlien Masuter Pro – Best all-around build quality and spindle performance

- FoxAlien Masuter 4040 – Reliable motion control; survived longest runtime tests

- SainSmart Genmitsu PROVerXL 4030 – Large cutting area with braced Y-axis support