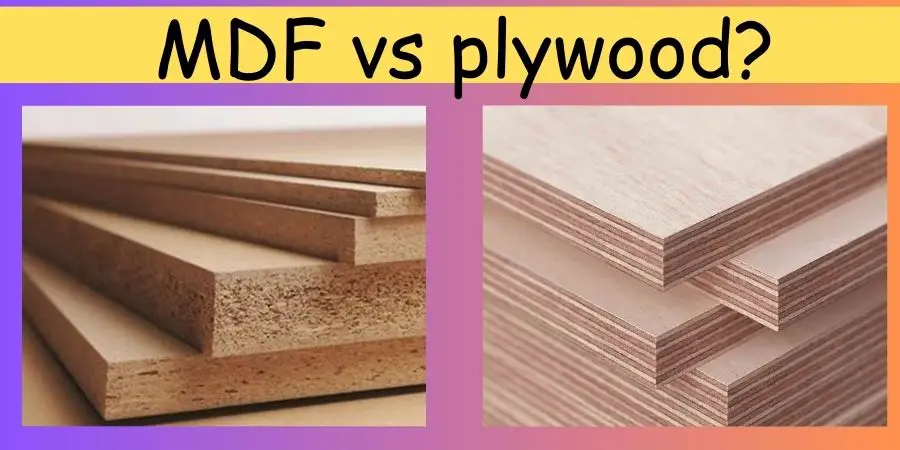

If you’re in the market for some new woodworking materials, you might be wondering whether plywood or MDF is the better choice. Today, we’ll be breaking down the pros and cons of each material so you can make an informed decision.

Table of Contents

MDF vs Marine plywood- The Main Difference

One of the biggest differences between MDF and marine plywood is their water resistance. MDF is not water-resistant and should never be used in wet or damp areas. It is known to swell and warp when exposed to moisture, which can cause it to lose its shape and integrity.

MDF, or medium-density fiberboard, is made by breaking down hardwood or softwood residuals into wood fibers and then combining them with wax and a resin binder. The mixture is then formed into panels by applying high temperature and pressure. MDF is known for its smooth surface and uniform density.

Marine plywood, on the other hand, is made by gluing together several thin layers of wood veneer with waterproof adhesive. The layers are arranged so that the grain of each layer is perpendicular to the adjacent layers, giving it strength and stability.

Choosing the Right Board for Your Project

When deciding between MDF and plywood, it’s important to consider the specific needs of your project. If you’re looking for a board that’s easy to work with and has a smooth surface, MDF might be the better choice. But if you need a board that’s strong and stable, plywood is the way to go.

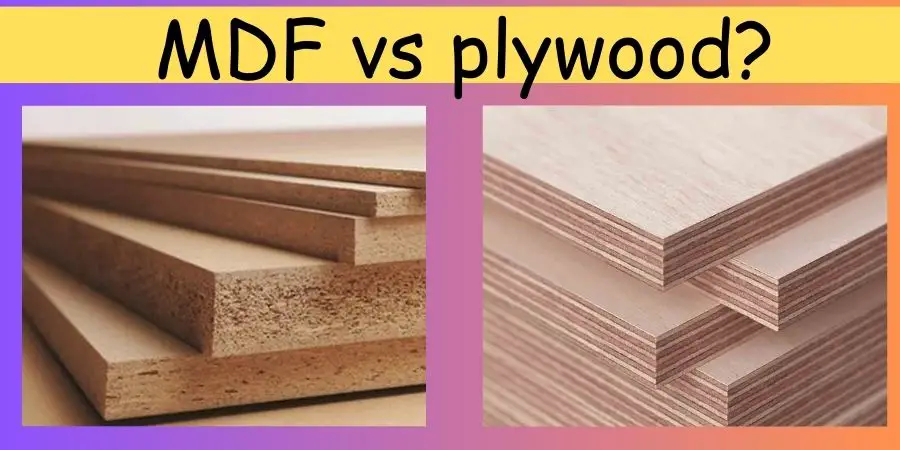

What is Plywood?

Plywood is made by gluing together thin layers of wood veneers, with each layer being placed perpendicular to the one below it. This cross-grain construction gives plywood its strength and durability.

Pros of Plywood:

- Strong and durable: Plywood is much stronger and more durable than MDF, making it a great choice for structural applications.

- Water-resistant: Certain types of plywood are water-resistant and can be used in wet environments.

- Easy to work with: Plywood is relatively easy to cut and shape, making it a favorite of both professional carpenters and DIYers.

Cons of Plywood:

- Can be expensive: High-quality plywood can be expensive, especially if you need a large amount for a project.

- Not always aesthetically pleasing: While some types of plywood have a beautiful wood grain, others can look bland or unattractive.

What is MDF?

MDF, or Medium-Density Fiberboard, is made by compressing wood fibers with a resin binder at high temperatures and pressure. The result is a dense and sturdy material that’s perfect for furniture, cabinets, and flooring.

Pros of MDF:

- Smooth surface: MDF has a very smooth and consistent surface, which makes it ideal for painting and finishing.

- Easy to work with: MDF is relatively easy to cut, shape, and drill, making it a favorite of DIYers.

- Affordable: MDF is generally cheaper than plywood, which makes it a great choice for those on a budget.

Cons of MDF:

- Not water-resistant: MDF is not water-resistant, which means it can swell and warp when exposed to moisture.

- Not as strong as plywood: MDF is not as strong as plywood, so it’s not suitable for structural applications.

Plywood vs. MDF: Who Will Win in a Water Battle?

If you’re looking for a material to use in wet environments, such as a bathroom or a kitchen, you might be wondering which one is better for water resistance: plywood or MDF. Let’s dive in and find out!

Plywood and Water

Marine Plywood has been a popular choice for boats and other watercraft for years because it can be treated to be water-resistant. Marine plywood, for example, is specifically designed to resist water and decay. However, not all types of plywood are created equal, and some are not suitable for wet environments.

Pros of Plywood for Water:

- Marine grade plywood is designed specifically for water resistance.

- Certain types of plywood can be treated to resist water and decay.

Cons of Plywood for Water:

- Not all types of plywood are water-resistant.

- Water can still seep into the layers of plywood and cause damage over time.

MDF and Water

MDF is not naturally water-resistant, and it can swell and warp when exposed to moisture. This means that it’s not a great choice for areas where there’s a lot of water or humidity.

Pros of MDF for Water:

- None, MDF is not suitable for water environments.

Cons of MDF for Water:

- Not water-resistant.

- Can easily swell and warp when exposed to moisture.

The Verdict

When it comes to water resistance, plywood is the clear winner. While not all types of plywood are suitable for wet environments, there are specific types designed to be water-resistant, making them a better choice than MDF.

FAQ section:

Q: Can MDF be used in wet areas?

A: No, MDF is not suitable for wet areas as it can easily swell and warp when exposed to moisture.

Q: Can plywood be used in wet areas?

A: Yes, plywood can be used in wet areas, but it needs to be treated to resist water and decay.

Q: What is marine plywood?

A: Marine plywood is a type of plywood that’s specifically designed for water resistance and decay resistance.

Q: Can marine plywood be used for non-marine applications?

A: Yes, marine plywood can be used for non-marine applications, but it’s typically more expensive than regular plywood.

Q: How is marine plywood different from regular plywood?

A: Marine plywood is made with waterproof glue and has fewer voids and gaps between layers, making it more water-resistant and stable than regular plywood.

Q: Can plywood be waterproofed?

A: Yes, plywood can be waterproofed with sealers or coatings, but it’s important to note that this won’t make it as water-resistant as marine plywood.

Q: Is MDF water-resistant?

A: No, MDF is not water-resistant and should not be used in wet areas.

Q: Can MDF be treated to be water-resistant?

A: No, MDF cannot be treated to be water-resistant. It’s best to use a different material for wet areas.

Q: Can MDF be used for outdoor projects?

A: No, MDF is not suitable for outdoor projects as it can easily swell and warp when exposed to moisture.