There is a range of MDF board types, the blog discusses them each.

If you are looking for different grades of the MDF board, here are these.

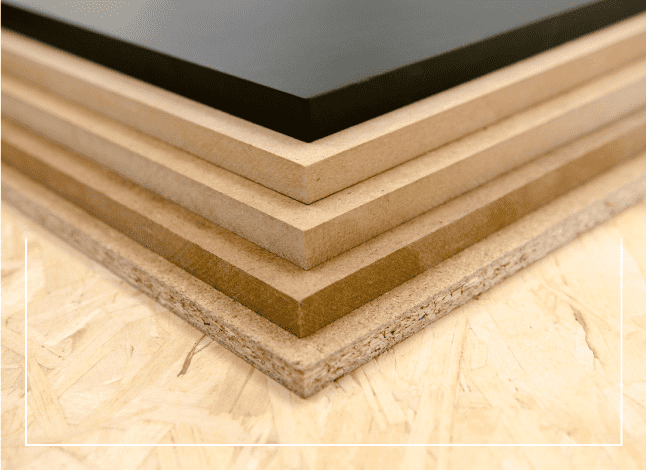

But before mentioning the types. You should be well aware of the fact that MDF is a broad term, used for chipboard, plywood, and MDF. There is a difference between each.

- MDF: The material is made of wood fibers, pressed harder.

- Chipboard: Wood fibers but are not pressed harder. MDF vs Chipboard

The difference between MDF and chipboard particularly lies between MDF being denser while chipboard is less dense.

- Plywood: it’s material made of thin layers of wood, glued together in a crossed-grain pattern to build quality wood.

Table of Contents

7 Types of MDF boards

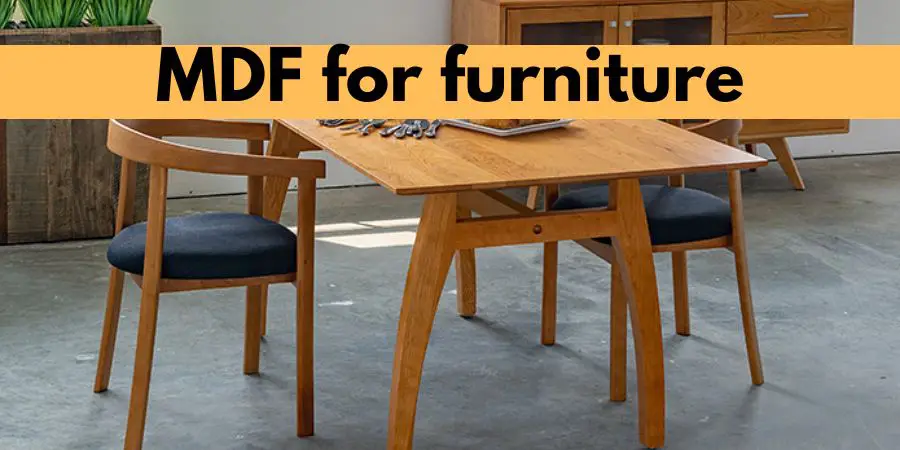

MDF or Medium Density Fiberboard is an engineered wood made up of wood fibers, creating panels under high pressure and high temperatures.

MDF is extremely versatile and used for its strength, durability, and consistency. MDF has a smooth and flat surface, making it great for wall paneling and cabinet doors

Regular MDF

MDF is typically much denser and heavier than plywood due to its composition of refined wood chips. Wood fibers are glued after heating and pressing.

The modulus of elasticity of regular MDF is very low, meaning that it is a stiff material, easily breakable.

The type of MDF board is cheaper than others as it’s standard, meaning there is no treatment applied to them.

MDF Ultra Lite

Despite having the same characteristics as regular MDF, MDF Ultra Lite has a lower density and is lighter in weight, allowing it to be handled easier. The lighter density makes it a good choice for building lighter-weight projects.

Weight and density are the most important factors for nonstructural applications using MDF Ultra Lite. Mostly it’s used in building projects that don’t have to hold heavy weights.

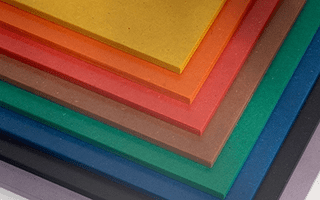

Colored MDF

A colored MDF substrate provides designers, architects, and woodworkers with a colorful substrate that enhances specific projects.

Although you can color regular MDF, this type of MDF is treated with extra treatment; it’s more than just color. Moreover, the appealing look allows the MDF board to be used for building kitchen cabinets.

Moisture Resistant

MDF designed to withstand moist conditions is moisture resistant. If you live in a city where you’ve to deal with the weather, this is gonna be the best choice for you then.

With its ability to resist water, you can be assured that the furniture will last for years to come.

No Added Formaldehyde

The lowest formaldehyde level is specified by NAF, meaning MDF has the lowest formaldehyde content. It’s ideal for people that want to avoid the risk of allergies as Regular MDF are known to be toxic, due to the high content of chemicals like urea formaldehyde.

In case you’re not aware of what formaldehyde is: Formaldehyde is an odorless, colorless chemical compound containing hydrogen, oxygen, and carbon.

Fire Rated

Building regulations mandate the use of Fire Rated MDF where performance enhancement is required. It’s suitable to be used where the risk of getting fired is high. As it’s treated with chemicals that make it slow-fire-spread material.

Exterior Grade MDF

MDF that is designed for exterior use has greater density and strength, which makes it more durable than regular MDF. The type of MDF is ideal for outdoor uses, as the name speaks that it’s treated with chemicals that enable it to be used for outdoor furnishings. Read more: Using MDF for outdoors.

Moisture, termites, and fungi are resistant to MDF used for exterior projects.