Chipboard and MDF (Medium Density Fiberboard) are both engineered wood products that are commonly used in furniture and cabinetry.

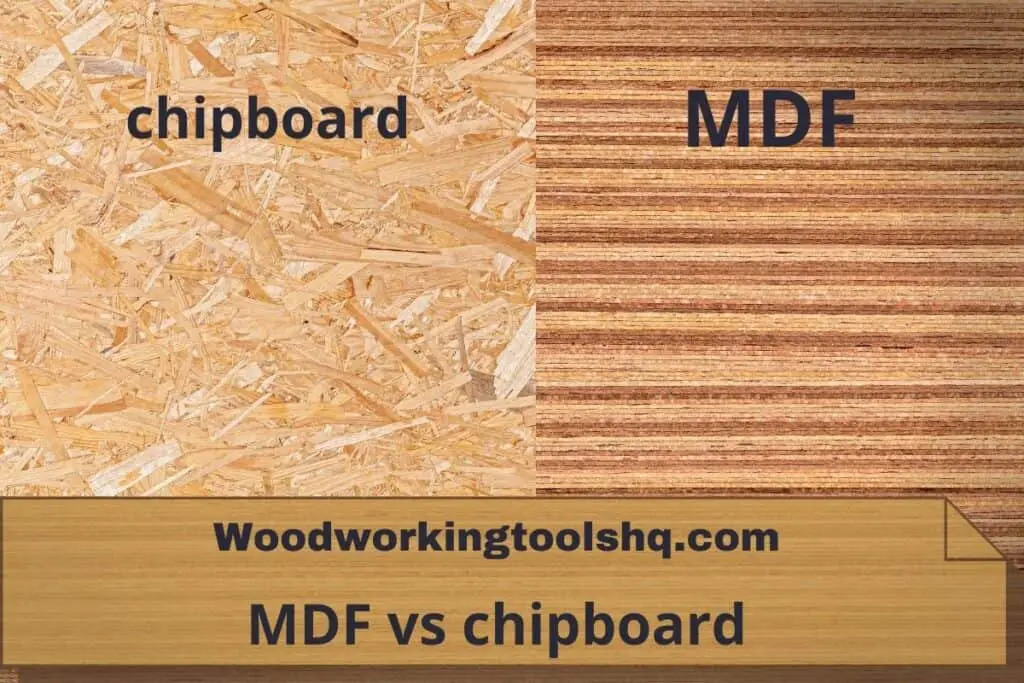

The main difference between them is the density of wood fibers used in their manufacturing process.

MDF is the name suggest are Medium Density Boards and where as chipboards, and other particleboards are known as Low density boards. There is also HDF board, which is denser than MDF.

The difference in their density can be seen by looking the at boards.

In short: MDF has more wood fibers per area compared to chipboard and other particle boards, which make it and heavier, also stronger.

MDF vs Chipboard- Comparison Table

Here’s the ummarize the key differences between MDF and chipboard in a comparison table:

| Factor | MDF (Medium-Density Fiberboard) | Chipboard (Particleboard) |

|---|---|---|

| Composition | Wood fibers, resin, and wax | Wood chips, shavings, and resin |

| Durability | Strong and durable | Less durable, prone to damage |

| Surface Finish | Smooth and great for finishing | Uneven texture, may require more effort |

| Strength | Less prone to sagging or breaking | Weaker, less stable under heavy loads |

| Weight | Relatively heavy | Lighter due to wood chips |

| Cost | Slightly more expensive | Economical option |

| Application Diversity | Intricate detailing, precision work | Less intricate applications |

| Environmental Impact | VOC emissions from resins | VOC emissions from resins |

| Moisture Resistance | Susceptible to moisture | Slightly better resistance |

| Machinability | Easy to machine and cut | More chipping and splintering |

| Screw Holding | Solid screw holding ability | Weaker screw holding, requires precautions |

| Acoustics | Better acoustic properties | Less effective for noise reduction |

| Sustainability | Less recyclable, improving methods | More recyclable, wood particles |

| Best Use | Fine detailing, stability | Temporary fixtures, budget-conscious projects |

MDF vs Chipboard- 12 Differences

1. Composition and Manufacturing

MDF: Medium-Density Fiberboard is crafted from wood fibers, combined with resin and wax, under high temperature and pressure. This creates a dense and uniform board that’s easy to work with and offers a smooth surface for finishing.

Chipboard: Chipboard, also known as particleboard, is made by compressing wood chips, shavings, and resin together. It’s an economical option but tends to have a more inconsistent texture compared to MDF.

2. Durability and Strength

MDF: Due to its tightly compacted fibers and manufacturing process, MDF is stronger and more durable than chipboard. It’s less prone to sagging or breaking under heavy loads, making it suitable for furniture and cabinetry that require stability.

Chipboard: Chipboard is generally less durable than MDF and is more susceptible to damage from moisture and impacts. It’s best used in projects where heavy-duty strength isn’t a primary concern.

3. Surface Finish

MDF: Thanks to its smooth surface, MDF is an excellent choice for projects that demand a flawless finish. It’s highly receptive to paints, veneers, and laminates, resulting in a polished and professional appearance.

Chipboard: The uneven texture of chipboard can pose challenges when it comes to achieving a smooth finish. While it can be painted or covered with veneer, it might require more effort to achieve the desired aesthetic.

4. Weight and Density

MDF: Despite its density, MDF is relatively heavy. This can be advantageous for stability but might pose challenges for larger projects or items that require frequent movement.

Chipboard: Chipboard is lighter than MDF due to its composition of wood chips and resin. This can make it easier to handle and transport, especially for larger-scale installations.

5. Cost Considerations

MDF: Generally, MDF is slightly more expensive than chipboard due to its manufacturing process and enhanced durability. However, the extra cost can be justified by the longevity and higher quality finish it offers.

Chipboard: Chipboard is often chosen for its cost-effectiveness, making it a practical option for projects with budget constraints. It’s a suitable choice for temporary fixtures or projects where aesthetics are of secondary importance.

6. Application Diversity

MDF: With its smooth surface and excellent machinability, MDF shines in intricate detailing and precision work. It’s a top choice for crafting decorative moldings, intricate carvings, and cabinetry with intricate designs.

Chipboard: Chipboard’s more rugged texture and lower density make it suitable for less intricate applications. It’s often used in projects like subflooring, underlayment, and temporary fixtures where fine detailing isn’t a priority.

7. Environmental Considerations

MDF: Medium-Density Fiberboard typically contains resins that can emit volatile organic compounds (VOCs). However, newer formulations and eco-friendly options are available, which minimize these emissions, making them a better choice for indoor use.

Chipboard: Chipboard also contains resins that can release VOCs. While it’s generally considered less eco-friendly than MDF, low-emission and FSC-certified chipboard products are emerging to address these concerns.

8. Moisture Resistance

MDF: MDF is highly susceptible to moisture and tends to swell or disintegrate when exposed to water. It’s not suitable for areas with high humidity or potential water exposure.

Chipboard: While still not the best choice for damp environments, chipboard can hold up slightly better against moisture compared to MDF. However, prolonged exposure to water can still lead to swelling and warping.

9. Machinability and Cutting

MDF: MDF’s uniform composition and density make it exceptionally easy to machine and cut. It’s less likely to splinter or chip during cutting, making it ideal for intricate woodworking tasks.

Chipboard: Chipboard’s composition of wood particles can lead to more chipping and splintering during cutting, especially along the edges. Careful handling and proper tools are essential to achieve clean cuts.

10. Screw Holding Ability

MDF: MDF offers solid screw holding ability due to its dense composition. However, it’s important to use proper techniques, such as pre-drilling, to prevent the material from splitting.

Chipboard: Chipboard’s lower density can result in weaker screw holding. It’s advisable to use techniques like pilot holes and screws designed for chipboard to enhance stability.

11. Noise and Acoustics

MDF: Thanks to its density, MDF has better acoustic properties compared to chipboard. It’s often used in applications where noise reduction is important, such as speaker cabinets and furniture pieces.

Chipboard: Chipboard’s more porous composition makes it less effective in reducing noise. It’s better suited for applications where acoustics are not a significant concern.

12. Sustainability and Recycling

MDF: MDF’s use of wood fibers makes it a bit more challenging to recycle, especially when it’s been treated with adhesives or finishes. However, efforts are being made to improve recycling methods for MDF waste.

Chipboard: Chipboard’s composition of wood particles makes it more recyclable than MDF. Unfinished chipboard can often be repurposed more easily.

Which one Should i use- which is better?

Choose MDF (Medium-Density Fiberboard) If:

- Smooth Finish: If achieving a flawless and smooth finish is crucial for your project, MDF’s uniform surface is ideal. It takes well to paints, veneers, and laminates, making it perfect for furniture or items where aesthetics matter.

- Strength and Durability: MDF’s dense composition makes it stronger and more durable than chipboard. It’s suitable for projects requiring stability and the ability to withstand heavy loads.

- Precision Work: MDF’s machinability and resistance to chipping make it an excellent choice for intricate detailing, precision cuts, and fine woodworking.

- Acoustic Properties: If your project involves sound reduction, such as speaker cabinets or soundproofing elements, MDF’s better acoustic properties make it a preferred choice.

Choose Chipboard (Particleboard) If:

- Cost-Effectiveness: If you’re working on a budget-conscious project, chipboard’s affordability makes it an attractive option for temporary fixtures or projects where aesthetics are of secondary importance.

- Lighter Weight: Chipboard’s lower density makes it lighter, which can be advantageous for larger-scale installations or projects where frequent movement is required.

- Environmental Impact: While both materials have environmental considerations, chipboard may have slightly lower VOC emissions and could be considered more eco-friendly.

- Less Intricate Applications: For projects where intricate detailing isn’t a priority, such as subflooring, underlayment, or basic furniture, chipboard’s rugged texture might suffice.