When it comes to choosing the right material for a woodworking project, two popular options are plywood and particle board.

Both materials have their own advantages and disadvantages, and understanding the differences between the two can help you make an informed decision.

Difference between plywood and particle board?

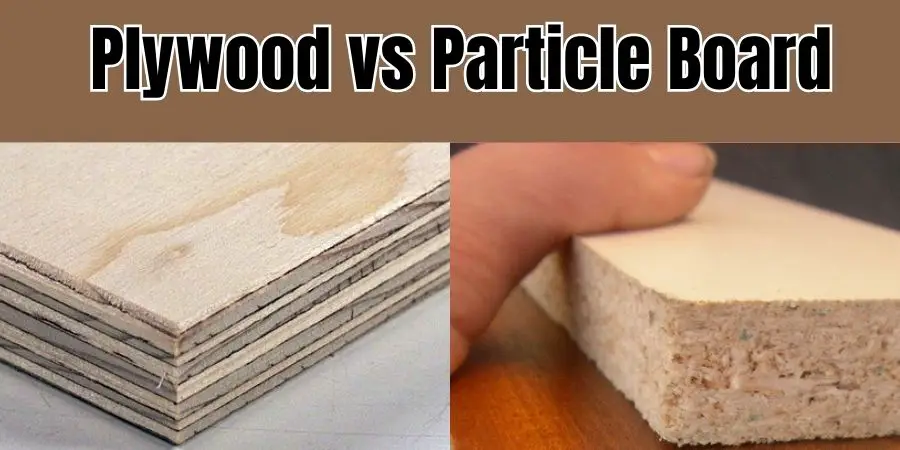

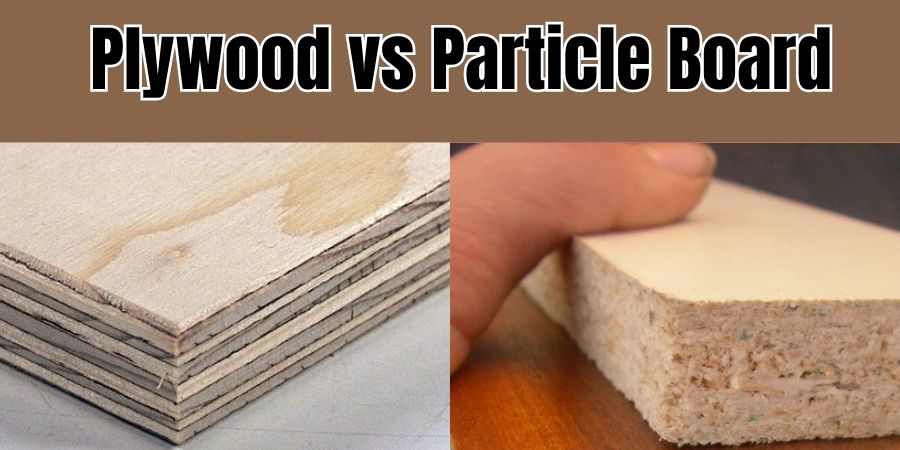

Plywood is made by layering thin sheets of wood veneer together with adhesive, while particle board is made from wood particles mixed with resin and compressed to form a uniform panel. Plywood is generally stronger and more durable, while particle board is more affordable.

So, If you’re looking for strength and durability, plywood is generally the better option. It’s made by layering thin sheets of wood veneer together with adhesive, creating a cross-grain construction that gives it excellent stability. It’s also less susceptible to moisture damage than particle board.

However, if cost is a major factor, particle board is often the more affordable choice. It’s made from wood particles mixed with resin and compressed to form a uniform panel. While it may not be as strong or durable as plywood, it’s still a good choice for low-cost furniture and cabinets.

Composition and Structure

Plywood

Plywood is made by layering thin sheets of wood veneer together with adhesive, with each layer placed perpendicular to the previous one. This cross-grain construction gives plywood its strength and stability. It comes in various grades, with different thicknesses and qualities available for different applications.

OSB

On the other hand, particle board is made from wood particles, such as sawdust and wood shavings, that are mixed with resin and compressed under high pressure and temperature to form a dense, uniform panel. The surface of particle board is usually covered with a veneer or laminate to improve its appearance and durability.

Strength and Durability

Plywood is known for its strength and durability. The cross-grain construction of plywood gives it excellent structural stability, making it suitable for a variety of applications that require a strong and stable surface.

However, the strength of plywood can vary depending on its quality and thickness.

Particle board, on the other hand, is less strong and durable than plywood. It has a tendency to sag or break under heavy weight, and is susceptible to moisture damage.

However, particle board is less expensive than plywood, making it a popular choice for low-cost furniture and cabinets.

Appearance and Finish

Plywood has a natural wood grain that gives it an attractive appearance. It can be stained, painted or varnished to achieve a desired look, and is available in a variety of wood species and finishes.

Particle board, on the other hand, has a uniform and consistent surface that may not have the natural wood grain of plywood. However, it can be covered with a veneer or laminate to improve its appearance and make it look like real wood.

Cost

In general, particle board is less expensive than plywood. This is because particle board is made from waste wood materials, while plywood is made from high-quality wood veneers. However, the cost of plywood can vary depending on its grade, thickness and quality.

Plywood vs particle board- Pros and cons

Pros and Cons of Plywood:

Pros:

- Plywood has excellent strength and durability due to its cross-grain construction.

- It is available in a variety of grades, thicknesses, and finishes, making it suitable for a wide range of applications.

- It has a natural wood grain that can be finished to achieve a desired look.

- It is less susceptible to moisture damage than particle board.

Cons:

- Plywood can be more expensive than particle board, especially higher grades.

- The strength of plywood can vary depending on its quality and thickness.

- Plywood may not have a uniform appearance due to the natural wood grain, which can make matching pieces difficult.

- Plywood may be prone to warping or bowing if not stored or used correctly.

Pros and Cons of Particle Board:

Pros:

- Particle board is less expensive than plywood, making it a popular choice for low-cost furniture and cabinets.

- It has a uniform and consistent surface that can be covered with a veneer or laminate to improve its appearance.

- It is easy to work with and can be cut and shaped with basic woodworking tools.

- It is made from waste wood materials, making it a more sustainable option than solid wood.

Cons:

- Particle board is less strong and durable than plywood, and may sag or break under heavy weight.

- It is more susceptible to moisture damage than plywood.

- The surface of particle board can chip or peel if not covered with a protective veneer or laminate.

- It may emit formaldehyde or other chemicals, which can be harmful to health if not properly ventilated.

FAQ section:

Q: Can plywood and particle board be used for the same applications?

A: Yes, both plywood and particle board can be used for a variety of applications, including furniture, cabinets, and building construction. However, the choice between the two depends on the specific requirements of the project.

Q: Is plywood or particle board more susceptible to moisture damage?

A: Particle board is generally more susceptible to moisture damage than plywood. Plywood has a cross-grain construction that makes it more stable and less prone to warping or bowing due to moisture.

Q: Is plywood or particle board more sustainable?

A: Particle board is generally considered more sustainable than plywood because it is made from waste wood materials, while plywood requires the use of whole logs. However, the sustainability of both materials depends on the specific production methods used.

Q: Can plywood and particle board be painted or stained?

A: Yes, both plywood and particle board can be painted or stained. Plywood has a natural wood grain that can be finished to achieve a desired look, while particle board is usually covered with a veneer or laminate to improve its appearance.