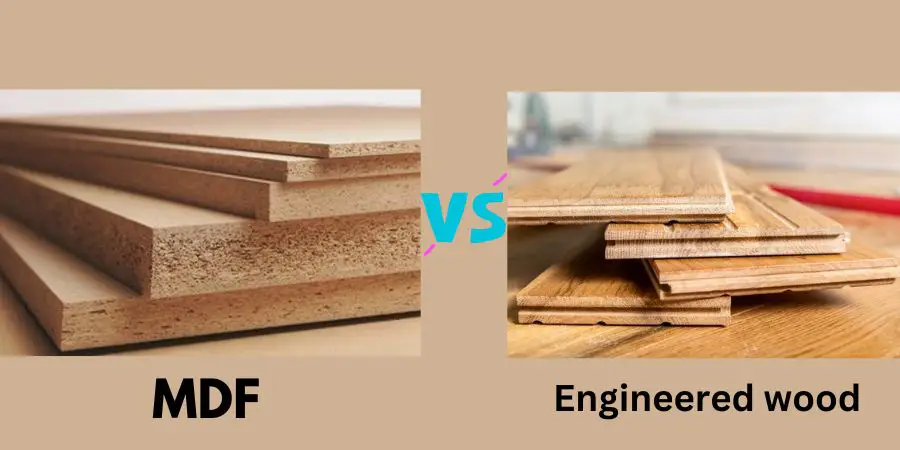

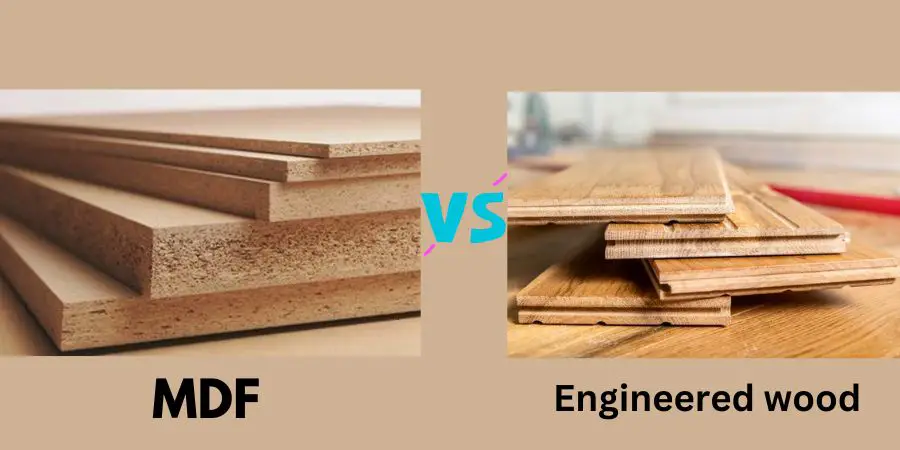

The fact is, MDF is also an engineered wood since it’s made in a factory so it’s a kind of engineering. However, the engineered wood term is mostly used for plywood, OSB, laminated veneer LVL, etc.

Key points

The main difference between MDF and other engineered wood lies in how they are manufactured. MDF is made from pressing and combining wood fibers while many other engineered kinds of wood are made by combining wood layers to form a thicker board.

So taking engineered wood as plywood, here’s the difference between MDF and engineered wood you should know.

What is MDF?

Medium Density Fiberboard (MDF) is also a type of engineered wood made by combining wood fibers with a resin binder and pressing them together at high temperatures and pressure. MDF is an affordable and versatile material that is easy to work with, making it popular in the furniture industry. It is known for its uniformity, smooth surface, and high strength-to-weight ratio.

What is Engineered Wood?

Engineered wood is a type of wood composite made by combining wood veneers, fibers, or particles with adhesives to create a material that is stronger and more durable than natural wood. It is available in a variety of forms, such as plywood, oriented strand board (OSB), and laminated veneer lumber (LVL). Engineered wood is a popular choice for construction and furniture-making because it offers the look of natural wood with added strength and durability.

Differences between MDF and Engineered Wood

While MDF and engineered wood are similar in that they are both composite materials, there are some key differences to consider when choosing between the two.

Composition

MDF is made by combining wood fibers with a resin binder, while engineered wood is made by combining wood veneers, fibers, or particles with adhesives.

Strength and Durability

Engineered wood is generally stronger and more durable than MDF due to its construction. It can also withstand moisture better than MDF, making it a better choice for outdoor furniture or areas with high humidity.

Cost

MDF is generally less expensive than engineered wood, making it a popular choice for those on a budget.

Surface Finish

MDF has a smooth and consistent surface finish, making it easy to paint or laminate. Engineered wood, on the other hand, can have a more natural and textured look, depending on the type of wood veneer used.

Engineered wood vs MDF- comparison table

Here is a table that outlines the differences between MDF and engineered wood:

| Category | MDF | Engineered Wood |

|---|---|---|

| Composition | Wood fibers combined with a resin binder | Wood veneers, fibers, or particles combined with adhesives |

| Strength and Durability | Generally less strong and durable | Generally stronger and more durable |

| Moisture Resistance | Absorbs moisture and can swell or warp | Better resistance to moisture and can withstand high humidity |

| Surface Finish | Smooth, consistent surface finish | Can have a more natural, textured look depending on the type of wood veneer used |

| Cost | Generally less expensive | Generally more expensive |

Conclusion

When choosing between MDF and engineered wood, it’s important to consider the specific needs of your project. If you’re looking for a more affordable option and a smooth, consistent finish, MDF may be the better choice. However, if you need a stronger, more durable material that can withstand moisture, engineered wood is likely the way to go.