Circular can be used to cut metal, but the right blade is needed to get the job done.

However, mind that a circular saw’s efficiency in cutting metals is not as good as a chop saw.

Yet, making rough cuts is possible on both types of metals ferrous and nonferrous.

Precision cutting is challenging, and you should not expect perfect angles by using a circular saw for metal cutting.

Table of Contents

best circular saw blades for metal

1. Diablo D0748CF STEEL DEMON 7 1/4 inch 48 Teeth

- Number of teeth: 48-Tooth

- Suitable for: Cutting Stainless Steel, Metal, wood

- Material: Stainless Steel, Alloy Steel

- Blade Size: 7 ¼

One of the best dual-purpose blades you can buy on amazon. This blade can be used for cutting sheet metal, 2″ x 4″s, 26 gauge metal roofing, and hardwoods. As long as the blade is used properly, it will cut approximately 50 feet of 18G sheet steel while the durability is reduced when cutting 24 gauge steel sheet.

However, it will still perform well on cutting wood as if it was brand new. For metal cutting, I definitely recommend this blade. The best part is it does not get overheated, has no burning, and leaves no burr when used on hard metals.

Cutting soft metals may not yield the best results, as fewer teeth (48) may not produce the smoothest cuts.

2. Irwin 4935560

- Number of teeth: 68-Tooth

- Suitable for: Cutting thin steel

- Material: Carbide

- Blade Size: 7 ¼

Perhaps you want your cordless circular saw to cut metal sheets, maybe it’s roofing steel roofing that needs to be cut. If your previous blade failed to get the job done.

Then, This 7-¼ is the blade you should give a try. First, on our list, the Irwin blade is the real deal to cut thin sheets of ferrous metal including stainless steel and iron as well.

You can use it for cutting rails as well, well some exceptions exist as too much thickness is not good for the blade (teeth get damaged). Anyhow, it gets the job done in most applications you may be expecting from a good blade.

3. Oshlun SBNF-0725650

- Number of teeth: 60-Tooth

- Suitable for: aluminum, copper, brass, bronze, and even some plastics

- Material: Professional Grade C-1 Carbide

- Blade Size: 7 ¼

- Topped: Triple Chip Tooth Grind

For cutting non-ferrous metals, like something made of aluminum sheet, or copper. Looking for a blade that will not only do the job perfectly but will last longer as well.

Oshlun SBNF 7 14 circular saw blade for metal is the best you can get. It makes cuts really smooth, leaving the edges smooth that do not require any further detailing.

The perfect teeth count which is 60 is the reason, coated with a premium grade carbide to last longer so you can hopefully use it for cutting 80 feet long sheets before the teeth get dulled.

Moreover, the teeth have a perfect angle (TCG), ideal for faster cutting and reducing the chances of kickbacks. But safety is always a priority, make sure you wear protective goggles and gloves before you start cutting aluminum.

4. Oshlun SBFT-210072A 210mm 72 Tooth

Photo: amazon.com

- Number of teeth: 72-Tooth

- Suitable for: Non-Ferrous Blade for Aluminum, Brass, Copper, Plastics, and More

- Material: Carbide

- Blade Size: 7 ¼

- Topped: Triple Chip Tooth Grind (TCG)

When cutting thick aluminum sheets or nonferrous metals, it can be difficult to make precise cuts as you need to make smooth-edged cuts.

Designed for dramatic burr reduction, this Oshlun saw blade often requires no additional work on the user’s part. The Oshun SBFT- blade with 72 teeth provides more accurate and precise cuts on thick sheets of aluminum.

Carbide material on the blade ensures its long-lasting performance that can allow you to cut around 100 feet of sheets before the blade gets damaged.

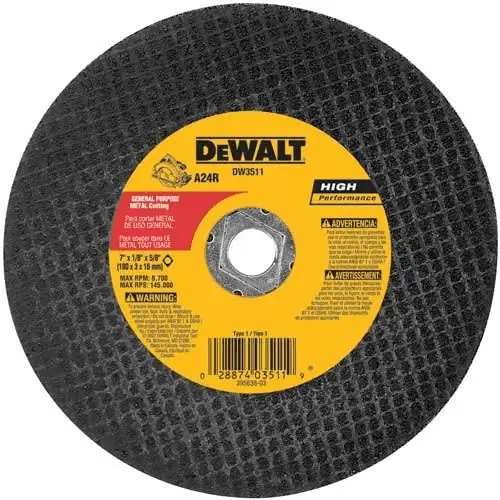

5. DEWALT 7-Inch Metal Cutting Blade, 5-Pack (DW3511B5)

- Number of teeth: Disc

- Suitable for: Thin metal, aluminum

- Material: silicon carbide grain

- Blade Size: 7 ¼

Designed for cutting nonferrous metals, including steel, bar stock, tubing, and studs, DEWALT Metal Cutting Chop Saw Wheels feature high concentration and high-performance aluminum oxide grain. If the other wood cutting blades have failed to complete the job you are working on.

Perhaps the material is thicker for those metal blades, but by using those blades with teeth the quality of cuts that you want is not being delivered.

That’s where you need this 7-¼ blade that is specifically designed to cut aluminum metal that is thicker than 1 inch. Cutting speed with this disc may be slower, and possibly the blade mat gets damaged after cutting a 20-feet long sheet.

But the end result is great, you can depend on this blade for cutting with precision. Again, speaking of its durability, the blade comes in a pack of 5.

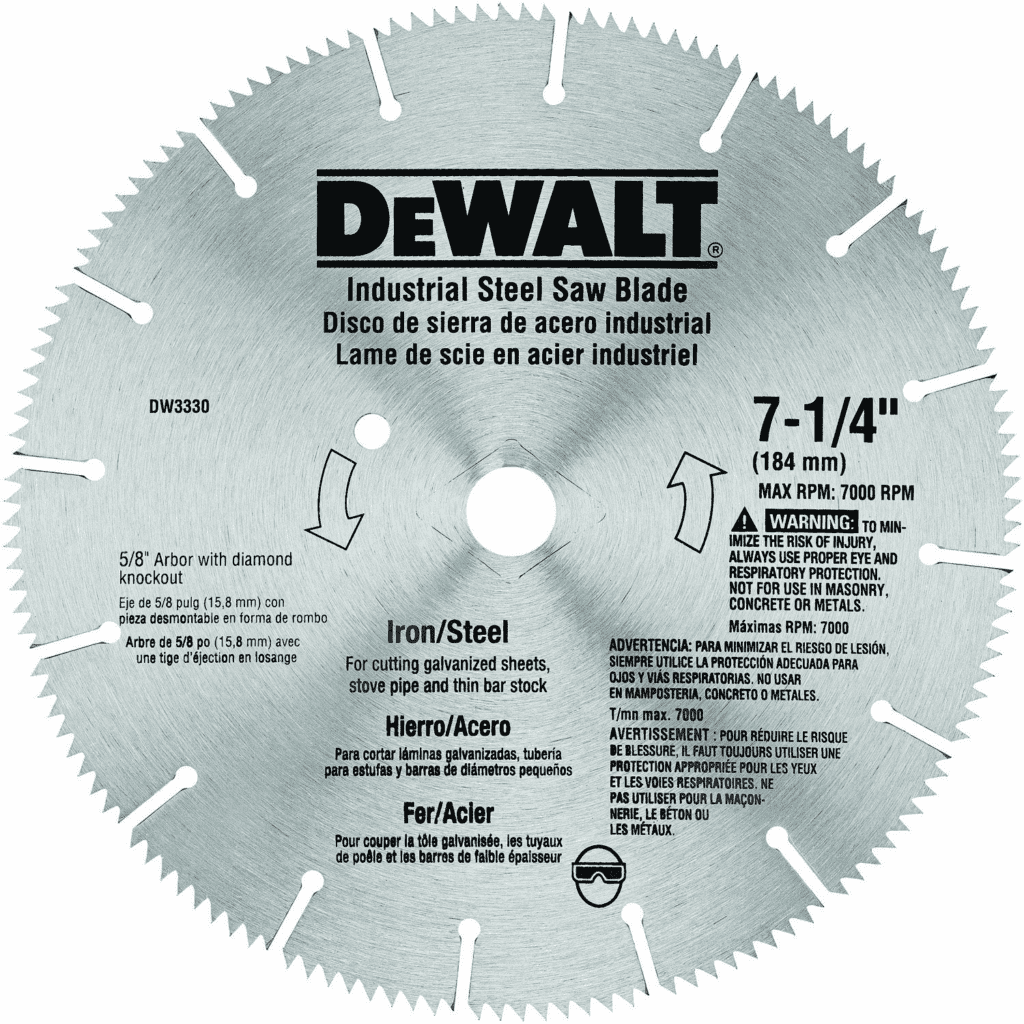

6. DEWALT DW3330

- Number of teeth: 72-Tooth

- Suitable for: Ferrous Material iron, stainless steel.

- Material: Alloy Steel

- Blade Size: 7 ¼

- Topped: Triple Chip Tooth Grind (TCG)

There are times when cutting faster is more important than cutting well. Mainly when it’s about cutting a pipe, railings, or aluminum roofing, where the right blade is which makes the cut faster. Try this Dewalt DW3330 7-¼ circular saw blade for cutting metal. Designed to cut thick metal such as thin sheets of steel, or ferrous metals.

Having 72 small teeth and gaps prevents the blade from overheating, which is ideal for cutting thin but hard ferrous metals. You should keep in mind that this blade might not provide the best results when cutting soft metals. Regardless, choose this blade when cutting thin sheets of steel, like railings or pipes. And more importantly, it could be your best partner to help you speed your rough cutting process.

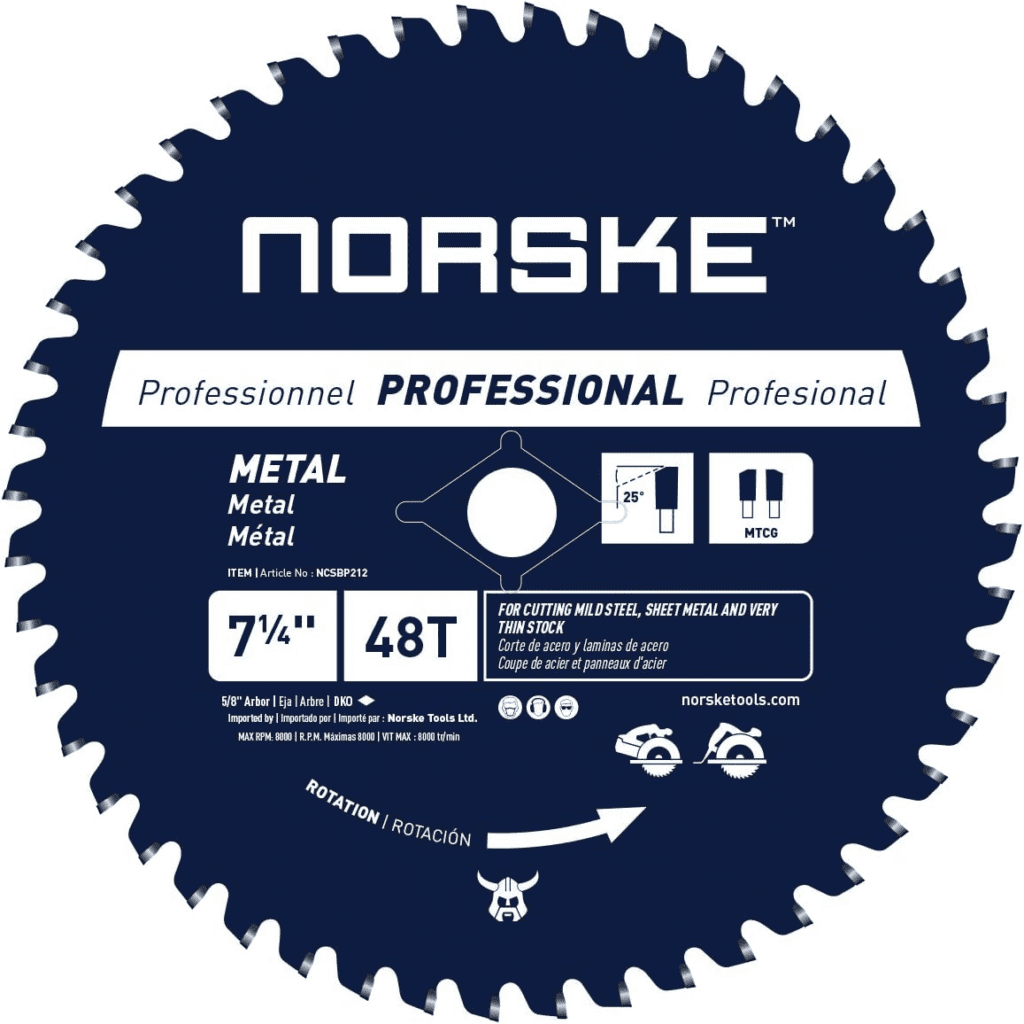

7. Norske Tools NCSBP212

- Number of teeth: 48-Tooth

- Suitable for: High-performance cutting of steel roofing, metal siding, steel pipe, steel studs, and more

- Material: C6 Micro-grain Carbide tips

- Blade Size: 7 ¼

- Topped: C6 Micro-grain Carbide tips Modified triple chip grind (MTCG) allows for easier cutting

It is probably not the best blade to cut through aluminum or soft materials such as plastic and fiberglass with this 7-14 blade for cutting metal. Nevertheless, it should only be used if you have a rough and hand material, such as a pile of iron and steel, or if you need to make angle cuts, but the cuts will not be of good quality. It’s more like cutting a bunch of waste pipes, thin sheets, and steel roofing.

What material is good for metal blades?

Non-ferrous metals, including those without iron, are soft. These are copper, aluminum, brass, etc. While metals with as include iron are hard metals like steel and stainless steel.

It is important to have the right blade if you plan to cut ferrous metals, because the blade must be made of ferrous material, like steel. In addition, ferrous blades are also capable of cutting through nonferrous metals. It is important to keep in mind that nonferrous blades cannot be used to cut through ferrous metals. For example, blades made of copper, aluminum, and brass can’t cut steel.

The blade of a metal tool should therefore be made from steel or stainless steel.

Number of teeth for a metal blade

Metal blades usually have more tooth count, ranging between 60-tooth to 140-tooths. It’s because of the denser nature of metals. Cutting metals effectively requires rapid succession. A metal blade’s more teeth enable it to provide smoother cuts, although this blade is likely to overheat on circular saws that rotate quickly. Contrary to that, metals cut better at slow speeds.

Type of circular saw blade for cutting metal

Blades with flat tips are ideal for cutting metal, the raker’s angle should be negative so the material does not come forward while ripping. Flat-topped blades are usually used to rip sheet material. Blade with Triple-chip grind (TCG) uses a flat top tooth, then a pointed tooth, and so on.

It’s opposed to a metal blade where the positive-raker is needed to cut faster, and tip is called ATP.