Dovetail joints are a type of woodworking joint that is commonly used to join two pieces of wood together.

These joints are known for their strength, durability, and unique aesthetic appeal.

However, like any woodworking joint, dovetail joints have their own set of advantages and disadvantages.

In this article, we will take a closer look at these pros and cons.

Table of Contents

Pros and cons of dovetail joints

Sure, here’s a table outlining the pros and cons of dovetail joints:

| Pros | Cons |

|---|---|

| Very strong and durable | Can be difficult and time-consuming to create |

| Aesthetically pleasing and visually appealing | Requires precision and skill to create |

| Provides a secure connection between two pieces | Can be more expensive than other types of joints |

| Versatile and can be used in a variety of projects | May not be necessary for all woodworking projects |

| Increases the value and longevity of the project |

Advantages of Dovetail Joints:

Strength: Dovetail joints are incredibly strong and durable. The interlocking design of the joint creates a solid connection between two pieces of wood, making it difficult for the joint to break or come apart. This makes them ideal for furniture that needs to withstand heavy loads or constant use.

Aesthetics: Dovetail joints are often used for their decorative appeal. The unique, interlocking design of the joint creates an attractive visual element that can enhance the overall look of a piece of furniture.

Versatility: Dovetail joints can be used in a wide variety of woodworking projects, from cabinets and drawers to bookcases and desks. They are particularly useful for creating strong connections between pieces of wood that will be subjected to stress and wear.

Longevity: Because of their strength and durability, dovetail joints are often used in furniture that is designed to last for generations. They can withstand the test of time and remain intact even after years of use.

Disadvantages of Dovetail Joints:

Difficulty: Dovetail joints can be difficult to create, particularly for beginners. The precise measurements and angles required to create a tight, strong joint can take practice to perfect.

Time–consuming: Because of their complexity, dovetail joints can be time-consuming to create. The process requires a high degree of precision and can take a considerable amount of time to complete.

Limited flexibility: Dovetail joints are not as flexible as some other types of joints. They are designed to be strong and durable, but this can also make them less forgiving when it comes to minor adjustments or changes.

Cost: Dovetail joints can be more expensive than other types of joints because of the time and skill required to create them. This can make them a less attractive option for those on a tight budget.

Common uses of dovetail join

Dovetail joints are commonly used in woodworking projects where strength, durability, and aesthetics are important. One of the most common uses of dovetail joints is in the construction of cabinets and drawers.

In cabinets

dovetail joints are used to connect the sides of the cabinet to the front and back panels. The joint creates a strong, interlocking connection that is able to withstand the weight of the cabinet and its contents.

This is important in cabinets that will be used to store heavy items or those that will be subject to regular use.

In drawers

dovetail joints are used to connect the sides of the drawer to the front and back panels. This creates a sturdy connection that is able to withstand the weight of the contents of the drawer, as well as the force of opening and closing the drawer.

Dovetail joints are particularly useful in drawers that will be used frequently, such as in a dresser or desk.

Dovetail joints are also commonly used in furniture such as chairs and tables, where the joint creates a strong connection between the legs and the top of the piece. This is important in furniture that will be subject to frequent use and movement, as the joint ensures that the piece remains stable and sturdy.

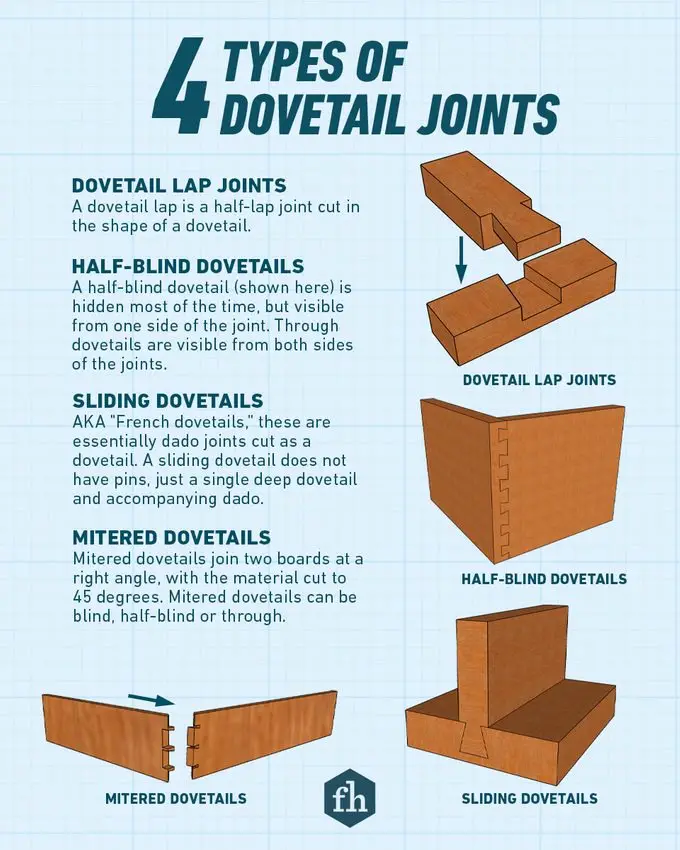

Types of dovetail joints.

credit: https://www.familyhandyman.com/article/everything-you-need-to-know-about-dovetail-joints/

There are several types of dovetail joints, each with their own unique characteristics and uses. Here are some of the most common types of dovetail joints:

Through Dovetail Joint: This is the most basic and commonly used type of dovetail joint. In this joint, the tails and pins of the joint are visible on both sides of the joint. This joint is commonly used in drawer construction and other woodworking projects.

Half-Blind Dovetail Joint: This joint is similar to the through dovetail joint, but the tails are not visible on the front side of the joint. This creates a more aesthetically pleasing joint, making it a popular choice for high-end furniture and cabinetry.

Full-Blind Dovetail Joint: In this joint, the tails and pins are not visible on either side of the joint. This creates a very clean, hidden joint that is often used in high-end furniture and cabinetry.

Sliding Dovetail Joint: This joint is used when two pieces of wood need to be joined at an angle, such as in a tabletop or cabinet. The joint is created by sliding one piece of wood into a slot cut into the other piece of wood, creating a strong connection.Secret Mitered Dovetail Joint: This joint combines a mitered joint with a dovetail joint, creating a hidden joint that is both strong and visually appealing. This joint is commonly used in high-end furniture and cabinetry.

Each type of dovetail joint has its own unique advantages and uses, and the type of joint used will depend on the specific needs and goals of the project.

Conclusion:

Dovetail joints are a popular woodworking joint that offers a range of advantages and disadvantages. They are incredibly strong and durable, making them ideal for furniture that needs to withstand heavy loads and constant use.

They are also versatile and can be used in a wide variety of woodworking projects.

However, they can be difficult and time-consuming to create, and they are less flexible than some other types of joints. Additionally, they can be more expensive than other types of joints, which may make them less attractive for those on a tight budget. Ultimately, the decision to use dovetail joints will depend on the specific needs and goals of the project.