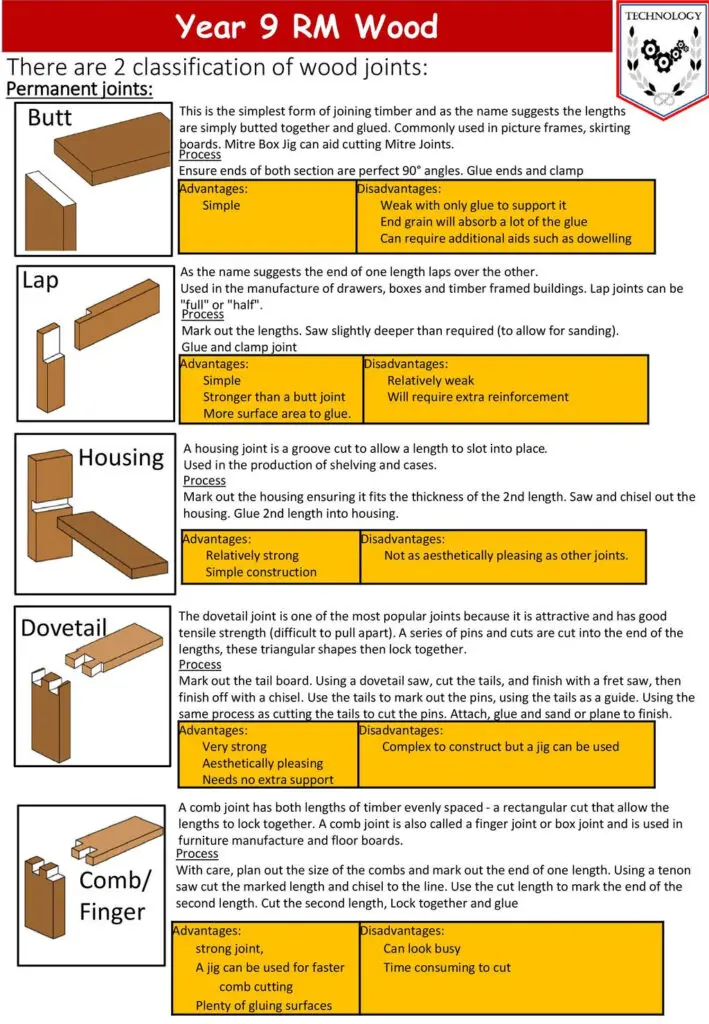

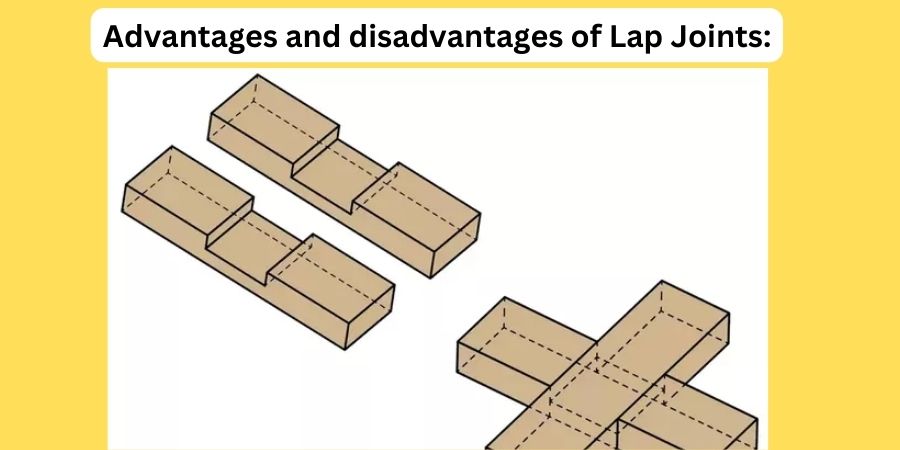

A lap joint is a type of joint used to connect two or more pieces of material, such as wood or metal. The joint consists of overlapping the two materials and securing them together with adhesive, nails, screws, or other fasteners.

Lap joints are commonly used in woodworking, metalworking, and construction. In this article, we will discuss the advantages and disadvantages of lap joints.

Table of Contents

Pros and cons of lap joints

Here are the pros and cons of lap joints presented in a table format:

| Pros | Cons |

|---|---|

| Increased Strength | Weakness at Corners |

| Easy to Create | Reliance on Adhesive |

| Versatile | Limited Structural Integrity |

| Discrete | Visible Overlap |

| No Specialized Tools Required |

Advantages of Lap Joints:

- Increased Strength: Lap joints increase the overall strength of the joint by providing a larger gluing surface area than other types of joints. This results in a stronger bond and increased resistance to bending and twisting forces.

- Easy to Create: Lap joints are relatively easy to create and require minimal tools and skills. They can be made using simple hand tools such as saws, chisels, and hammers.

- Versatile: Lap joints can be used in a variety of applications, including furniture making, construction, and metalworking. They can be used to join materials of different thicknesses, and can also be used to join materials at different angles.

- Discrete: Lap joints are discrete and do not show any signs of the joint on the surface of the material. This makes them a good choice for applications where a clean, seamless appearance is desired.

- No Specialized Tools Required: Unlike other joints such as dovetails, lap joints do not require specialized tools or machinery to create. This makes them accessible to hobbyists and DIY enthusiasts.

Disadvantages of Lap Joints:

- Reliance on Adhesive: Lap joints rely heavily on the adhesive used to bond the two pieces of material together. If the adhesive fails, the joint will fail as well.

- Limited Structural Integrity: Lap joints do not provide the same level of structural integrity as other joints such as mortise and tenon joints. They are more suitable for lightweight applications.

- Visible Overlap: While lap joints are discrete, they still have a visible overlap where the two pieces of material meet. This can be a disadvantage in applications where a seamless appearance is required.

Conclusion: Lap joints are a versatile and easy-to-create joint that can be used in a variety of applications. They offer increased strength and

Common uses of lap joints

Lap joints are commonly used in woodworking, metalworking, and construction for a variety of applications. Here are some situations where lap joints might be a good choice:

- Joining Materials of Different Thicknesses: Lap joints can be used to join materials of different thicknesses, such as thin metal sheets or wooden boards of different widths.

- Making Furniture: Lap joints are often used in furniture making to join table legs to table tops, or to attach rails and supports to chairs and benches.

- Joining Materials at Different Angles: Lap joints can be used to join materials at different angles, such as in the case of a chair back that needs to be attached to legs at an angle.

- Creating Lightweight Structures: Lap joints are suitable for creating lightweight structures, such as shelving units or trellises.

- Repairing Wood or Metal Structures: Lap joints can also be used to repair wood or metal structures, such as repairing a broken chair leg or reinforcing a metal frame.

In general, lap joints are a good choice when a strong and reliable joint is needed, but other joints may be too difficult or time-consuming to create. Additionally, lap joints are a good choice when a clean and discrete appearance is desired, as they do not show any signs of the joint on the surface of the material.

Resource: