From the kinds of screws out there. This blog post is about. What’s the difference between a Machine screw and wood screws.

Table of Contents

Wood screws vs machine screws.

Screws differ in their anatomy, not in length or thickness, nor the material from which they’re made.

Their overall structure is what creates differences between them. Threads, head, tip, shank, and some are tapered and non-tapered, meanwhile every screw is differ by considering one of these factors.

This goes the same for wood screws and machine screws.

- Wood screws have sharp threads and have shanks (slim body) at the neck part (below the head). Reducing the thickness from top to bottom ends up with sharp tips. These features allow wood screws to be self-drilled into the wood. But still, making pilot holes first has its own benefits.

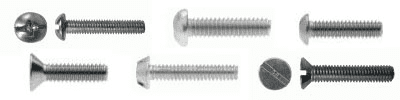

- Machine screws don’t have sharp threads as wood screws, instead, they are straight. Nor do they have the shanked part. Because of their non-tapered body, sharp tips are missing. These features allow the screws to be drilled only in holes with matching patterns. After installing, to fasten them up, bolts are used at the bottom.

Key points:

Wood screws have:

Sharp tips, thread, flatheads and can be self-drilled.

Machine screws have:

Straight threads, flat tips, require pilot holes.

Machine screw’s Characteristics?

- Fully threaded shank.

- Usually used with a nut.

- Typically smaller than the average screw.

- Designed to be fastened to an existing tapped hole.

- Flat points/tips.

- Heads can vary.

- Easy to remove.

Wood screws’s characteristics

- Partially threaded or fully threaded.

- Used without a nut.

- Difficult to take away or lose.

- Heads can vary, most are flat.

- Don’t require an existing hole.

- Self-drilled, sharp points or tips.

Can Machine screws be used on wood?

It’s typical to answer that. But off the bat,

NO. Machine screws are not supposed to be used on wood- some reasons lie here. Such as they don’t have sharp tips that can be drilled into the woods nor do they have sharp threads.

- If you try to fit a machine screw on a wood. You might end up breaking apart the wood piece. It will happen due to their flat base and straight threads.

Moreover, machine screws require a nut at the bottom to strongly tighten them.

Does it matter how screws look?

As mentioned above, screws differ in how they are structured. An array of screws are out there, based on their structure. Some work better for wood and others for metallic joints.

Particularly, to explore more about wood and machine screws. Understanding parts of screws will answer your many questions.

Every screw has the following parts:

- Head

- Body (shanked, or threaded)

- Tip

- Tapered or non-tapered

Head

Screws can have multiple kinds of heads that can be flat, rounded, squared, etc. Choosing the right head is necessary.

- For wood screws, flatheads are popular for a good reason. Since these screws are attached to the top surface. Looks almost invisible. The downside is, removing these screws is difficult and at worst the surface can be damaged.

- Machine screws mostly come with a rounded-shaped head. Easier to install and uninstall. However, these screws are problematic when used in wood as the head is not invisible, appealing a poor look.

Body

The body of any screw is the major part that explains the purpose of a screw where it is going to be fit.

Screws can have these bodies:

- Fully threaded:

- Partially threaded:

Fully threaded screws bodies are common for machine screws as they need to be fully drilled into the hole.

Partially threaded bodies have their own benefits. As the flat part (shank) makes a screw stronger than those fully threaded. Usually, wood screws have it.

Distance between threads is also an important factor to consider. This is known as pitch. A small and closely spaced thread is referred to as a small pitch thread. Typically, there are larger threads spaced farther apart in other screws (such as drywall anchors).

Moreover, the sharpness of the threads is also a thing to mention here.

- Wood screws have sharp threads, allowing them to be drilled into the wood. Sharp edges can adjust by digging into wood grains.

- Whereas the threads on the machine screws are not as sharp as wood screws. Using them for joining two wooden parts requires pilot holes, and conversely the joint would not be strong because the wood grains will not fully adopt the screw as screws with sharp threaded can.

Tip

The tip or point is the end part of any screw that is going to be drilled into a-holes. Flat are sharp are two choices to be found.

- Screws with flat tips are mostly lie in the Machine screws category. To install or drill these screws, a fixed pre-drilled hole is required with the same straight threads of the hole and on the screw.

- A good example of sharp tips screws would be wood screws. Because screws need to be drilled through the wood, sharp tips thus do the trick.

Tapered or non-tapered

The term tapered is used to define the entire body.

- Screws that reduce the thickness towards an end are known as tapered screws, allowing them to be installed without pilot holes. Non-tapered screws on the other hand are flat from one end to another.

Screws with sharp points are typically tapered and screws with flat points are non-tapered.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.