If you’re in the market for new furniture or home renovation materials, you may have come across the acronyms MDF and MDP. While these two materials may sound similar, they actually have some important differences to consider.

Table of Contents

MDF vs MDP- Compariosn Table

| Feature | MDF (Medium-Density Fiberboard) | MDP (Medium-Density Particleboard) |

|---|---|---|

| Composition | Fine wood fibers bonded with adhesive | Wood particles or chips bonded with adhesive |

| Density | Denser and stronger | Less dense, lighter |

| Smoothness and Finish | Provides a smoother, more refined finish | May not achieve the same level of precision |

| Weight | Heavier | Lighter, suitable for lightweight applications |

| Price | Generally more expensive | Typically more budget-friendly |

| Moisture Resistance | Susceptible to moisture damage | Better moisture resistance |

| Machinability | Easier to machine for precise cuts and edges | May require more effort for precision |

| Environmental Impact | Can contain formaldehyde-based adhesives | Some products use lower-emission or formaldehyde-free adhesives, potentially more eco-friendly |

| Sound Absorption | Better at sound absorption | Less effective for sound absorption |

| Edge Detailing | Allows for better edge detailing | Edges may be less refined |

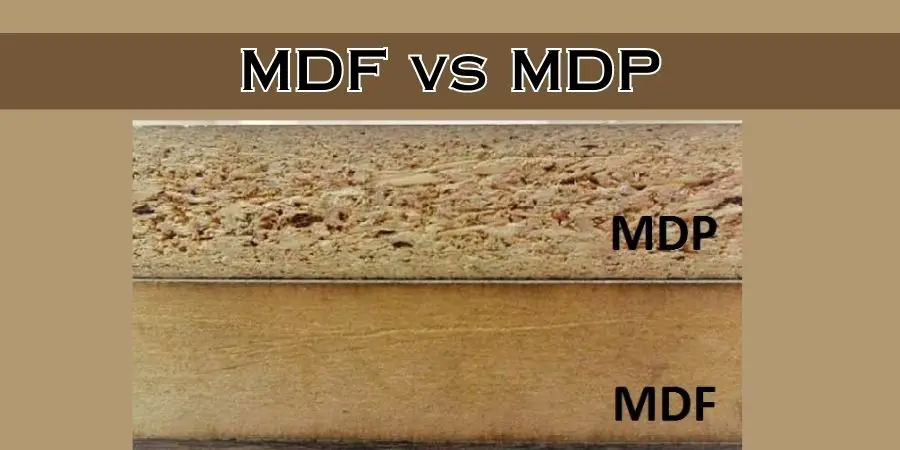

MDF is made of compressed wood fibers that make it super strong and uniform. Meanwhile, MDP is like the little brother who’s still growing – it’s made of larger wood particles that give it a more uneven texture and make it less strong overall.

Now, that’s not to say that MDP is a complete weakling.

It’s still a durable material that can handle normal wear and tear, and it’s often used for shelves, office furniture, and doors.

But if you’re looking for something that can stand up to heavy use, MDF is the way to go.

It’s great for furniture and cabinetry that need to be strong and long-lasting.

What is MDF?

MDF stands for medium-density fiberboard. As the name suggests, MDF is made from wood fibers that have been compressed and glued together to create a dense, uniform board.

MDF is known for its smooth surface and consistent thickness, which makes it a popular choice for furniture and cabinetry.

What is MDP?

MDP, on the other hand, stands for medium-density particleboard. Like MDF, MDP is made from wood particles that have been compressed and bonded together. However, MDP tends to have larger particles and a more uneven texture than MDF.

Strength MDP vs MDF

When it comes to strength, there are some important differences between MDF and MDP.

MDF is stronger and more durable than MDP because of its compressed wood fibers and uniform composition. It’s great for heavy-use furniture and cabinetry. MDP has a more uneven texture due to larger particles, so it’s not as strong, but still durable for shelves, office furniture, and doors.

It’s worth noting that the specific strength of MDF and MDP can vary depending on factors such as the density of the material and the quality of the manufacturing process. In general, however, MDF is considered to be the stronger of the two materials.

MDF vs MDP: Which is Better?

So, which one should you choose? Well, it depends on your specific needs and preferences.

Here are some factors to consider:

- Strength: MDF is generally stronger and more durable than MDP, thanks to its more uniform composition. If you’re looking for furniture that will withstand heavy use, MDF may be the better choice.

- Appearance: While both materials can be painted or veneered, MDF tends to have a smoother, more uniform surface. If you’re looking for a sleek, modern look, MDF may be the way to go.

- Cost: MDP is generally less expensive than MDF, which may make it a more attractive option for budget-conscious shoppers.

- Environmental impact: Both materials are made from wood fibers, which means they’re not the most eco-friendly option out there. However, some MDF manufacturers use recycled wood fibers, which can help reduce waste.

The Bottom Line

In the end, the choice between MDF and MDP comes down to your specific needs and preferences. If you’re looking for strength and durability, MDF may be the better choice. If you’re on a tight budget, MDP may be the way to go. Either way, you’ll end up with a sturdy, reliable material that will serve you well.

Common uses for MDF and MDP:

Uses for MDF:

- Furniture: MDF is a popular choice for furniture construction due to its smooth surface and consistent thickness. It can be easily cut, routed, and shaped into a variety of designs.

- Cabinetry: MDF is often used for kitchen and bathroom cabinets, as it is resistant to moisture and can be painted or veneered to match any style.

- Flooring: MDF can be used as a subfloor or underlayment for hardwood or tile flooring, as it provides a flat, stable surface.

- Decorative accents: MDF can be cut into decorative shapes and designs, making it a versatile choice for architectural features such as trim, molding, and wainscoting.

Uses for MDP:

- Shelving: MDP is a popular choice for shelving, as it can support heavy loads without sagging or warping.

- Wall panels: MDP can be used to create decorative wall panels, as its uneven texture can add visual interest and dimension.

- Office furniture: MDP is often used for office furniture such as desks and file cabinets, as it is durable and cost-effective.

- Doors: MDP can be used to create interior doors, as it is strong and resistant to warping.

similariteies between MDP and MDF

Absolutely! Here are some similarities between MDF and MDP:

- Material: Both MDF and MDP are composite materials made from wood fibers or particles that are compressed and bonded together.

- Density: Both materials are classified as medium-density, which means they have a density between that of solid wood and traditional particleboard.

- Versatility: Both MDF and MDP can be cut, routed, and shaped into a variety of designs, making them versatile materials for a wide range of applications.

- Finishing: Both materials can be painted, veneered, or laminated to achieve a desired finish or texture.

- Durability: While MDF is generally considered to be stronger and more durable than MDP, both materials are designed to be strong and long-lasting.

- Moisture resistance: While neither material is waterproof, both MDF and MDP have some resistance to moisture and can be used in humid environments such as kitchens and bathrooms.