When it comes to woodworking, a table saw is often the heart of the operation. Whether you’re a seasoned pro or just starting out, you’ve likely heard the term “rip capacity” thrown around. But what exactly is rip capacity, and why does it matter?

In this blog post, we’ll answer essential questions and help you grasp the importance of rip capacity in your woodworking endeavors.

Table of Contents

What Is Rip Capacity?

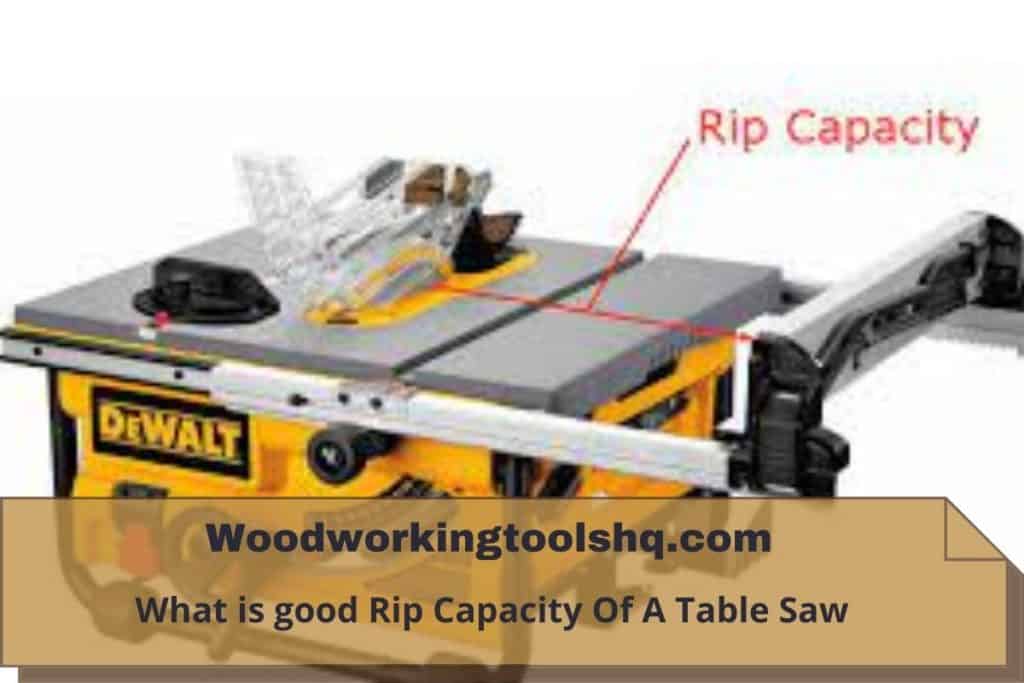

Rip capacity is a term that describes the maximum width of material you can safely cut on a table saw.

In other words, it’s the distance between the saw blade and the fence on the right side of the blade. This measurement is crucial because it determines the size of the stock you can work with.

Let’s break it down with an example. If your table saw has a rip capacity of 24 inches, it means you can make a straight cut through a piece of wood that is up to 24 inches wide.

Trying to cut anything wider than that would not only be risky but could damage your saw or result in an uneven, unsafe cut.

1. Why Does Rip Capacity Matter?

Now that we know what rip capacity is, let’s dive into why it’s so important.

1. Safety First

Safety should always be your top priority in woodworking. Using a table saw with a rip capacity that matches your project’s needs ensures that you can make accurate cuts without compromising safety. Attempting to cut materials wider than your saw’s capacity can lead to kickback, where the wood is violently thrown back towards you, posing a significant danger. It’s a situation you definitely want to avoid.

2. Versatility and Efficiency

Imagine you’re working on a project that requires you to cut a wide sheet of plywood for a cabinet back. If your table saw has a limited rip capacity, you’d have to resort to other, potentially less precise methods, like using a circular saw or a track saw. This not only reduces the accuracy of your work but also increases the time and effort required.

With a table saw boasting a generous rip capacity, you can tackle a broader range of projects efficiently and with greater precision. It becomes a versatile tool in your workshop, capable of handling a variety of tasks, from ripping long boards to cutting sheet goods.

2. How to Determine the Right Rip Capacity for You

So, how do you figure out the ideal rip capacity for your needs? Here are some steps to help you make an informed decision:

- Assess Your Projects: Consider the types of projects you frequently work on and the sizes of materials you typically use. Your rip capacity should comfortably accommodate the widest pieces you commonly encounter.

- Plan for Growth: If you’re an aspiring woodworker or foresee tackling larger projects in the future, it’s wise to invest in a table saw with a generous rip capacity from the get-go. This ensures you won’t outgrow your tool too quickly.

- Check the Market: Table saws come in various sizes and price ranges. Research the options available in your budget and read reviews to find a saw that suits your specific needs.

- Consider Aftermarket Upgrades: In some cases, you can extend the rip capacity of your table saw by purchasing aftermarket accessories or by building custom extensions. This can be a cost-effective solution if you already own a table saw with a smaller capacity.

3. Can I Increase the Rip Capacity of My Existing Table Saw?

Yes, you can often increase the rip capacity of your existing table saw through a few methods:

- Aftermarket Accessories: Many manufacturers offer extension wings or fences that can be added to your existing table saw. These extensions can significantly increase your saw’s rip capacity and versatility.

- Build Custom Extensions: For a more budget-friendly approach, you can build custom extensions using plywood or other suitable materials. Just make sure they are level and securely attached to maintain safety and accuracy.

- Retrofitting: Some experienced woodworkers have successfully modified their table saws by repositioning the fence rails to gain more rip capacity. However, this can be a complex task and may require advanced woodworking skills.

Before attempting any modifications, consult your table saw’s manual, and consider seeking advice from experienced woodworkers or professionals to ensure safety and precision.

4. What Is the Difference Between Rip Capacity and Crosscut Capacity?

Rip capacity and crosscut capacity are both essential measurements for understanding a table saw’s capabilities, but they refer to different aspects of cutting:

- Rip Capacity: As we’ve discussed, rip capacity is the distance between the saw blade and the fence on the right side of the blade. It determines the width of material you can cut lengthwise or parallel to the grain of the wood.

- Crosscut Capacity: Crosscut capacity, on the other hand, refers to the width of material you can cut perpendicular to the grain of the wood. This measurement is determined by the size of the miter gauge or the distance between the blade and any crosscut sled or accessory you use.

5. What Are Some Safety Tips When Using a Table Saw with a High Rip Capacity?

Safety is paramount when working with any power tool, especially one with a high rip capacity. Here are some essential safety tips to keep in mind:

- Always Wear Safety Gear: This includes safety glasses or goggles, hearing protection, and appropriate clothing. Additionally, consider using a dust mask or respirator to protect against dust and debris.

- Keep Your Work Area Clean: A clutter-free workspace reduces the risk of accidents. Ensure there are no obstructions near the saw, and clear away wood scraps and tools that you’re not using.

- Use a Push Stick: When making narrow cuts, use a push stick to guide the wood through the blade. This keeps your hands safely away from the blade and prevents kickback.

- Maintain Proper Blade Height: Adjust the blade height so it’s only slightly higher than the thickness of the material you’re cutting. This minimizes the exposed blade and reduces the chance of accidents.

- Use a Rip Fence: A rip fence is your best friend when making long rip cuts. Ensure it’s aligned correctly and securely locked in place to maintain a straight cut.

- Avoid Overloading the Saw: Don’t push the saw beyond its capabilities. If you’re working with large or heavy materials, get assistance or use additional support to prevent strain on the saw and reduce the risk of accidents.

- Stay Focused: Woodworking requires your full attention. Avoid distractions, and never rush through a cut. Take your time to ensure accuracy and safety.

6. Are There Any Limitations to Consider with a Table Saw’s Rip Capacity?

Yes, there are a few limitations to keep in mind:

- Cut Quality: While a table saw with a high rip capacity can handle wide cuts, the quality of those cuts can be affected by the type of blade you use, the saw’s power, and the stability of your setup. Investing in a quality blade and ensuring your saw is properly maintained will help maintain cut quality.

- Space Requirements: A table saw with a large rip capacity can take up a significant amount of space in your workshop. Ensure you have adequate room for both the saw and the materials you’ll be working with.

- Portability: Large table saws with high rip capacities can be heavy and challenging to move around. If you need to transport your saw frequently, consider a portable model with a smaller rip capacity.

- Budget: Table saws with larger rip capacities tend to be more expensive. Make sure your budget aligns with your needs and the type of projects you plan to undertake.

8. Do Different Types of Table Saws Have Different Rip Capacities?

Yes, different types of table saws can have varying rip capacities, and the type of table saw you choose should align with your specific needs:

- Contractor Table Saws: These are typically portable and have a moderate rip capacity suitable for a wide range of tasks, including general woodworking and construction projects. Rip capacity can vary but often falls in the 24-36 inch range.

- Cabinet Table Saws: Cabinet table saws are larger and more powerful, making them suitable for professional woodworkers and demanding projects. They often have larger rip capacities, frequently ranging from 36 to 52 inches or more.

- Compact Table Saws: These smaller table saws are designed for DIY enthusiasts with limited space. They have more modest rip capacities, usually around 18-24 inches.

- Hybrid Table Saws: Hybrid table saws bridge the gap between contractor and cabinet saws. They offer a good balance of power and portability and typically have rip capacities ranging from 30 to 40 inches.

9. Benefits of a Sliding Table Saw Regarding Rip Capacity?

A sliding table saw is a type of table saw known for its exceptional rip capacity and versatility. Here are some key benefits:

- Ample Rip Capacity: Sliding table saws have an extended sliding table that allows you to cut much wider materials compared to traditional table saws. This feature is especially advantageous when working with large sheets of plywood or other wide stock.

- Precision and Safety: The sliding table ensures accurate and controlled cuts, reducing the risk of kickback or misalignment common with standard rip fences. This precision is crucial for fine woodworking and cabinetry.

- Crosscut Capabilities: Sliding table saws are equally adept at crosscutting, making them versatile for various woodworking tasks. The sliding table allows you to make precise perpendicular cuts with ease.

- Efficiency: With a sliding table saw, you can make longer, continuous cuts without having to reposition your workpiece constantly. This streamlines the cutting process and enhances efficiency.

However, it’s important to note that sliding table saws are often larger, heavier, and more expensive than standard table saws, making them better suited for professional woodworkers or dedicated hobbyists with the space and budget for such equipment.

10. Can I Use a Table Saw with a Limited Rip Capacity for Larger Projects?

While it’s possible to use a table saw with a limited rip capacity for larger projects, it may come with certain challenges:

- Multiple Passes: If your table saw’s rip capacity is too small for the material you’re working with, you may need to make multiple passes to achieve the desired width. This can be time-consuming and may result in less precise cuts.

- Increased Risk: Making multiple passes or using unconventional methods to cut wider materials can increase the risk of accidents and kickback. It’s essential to exercise extreme caution in these situations and use appropriate safety measures.

- Accuracy Concerns: Achieving precise, straight cuts on larger materials with a limited rip capacity can be challenging. You might need to invest in additional tools like a straightedge guide or track saw to ensure accuracy.